Mandrel Straightening

Description

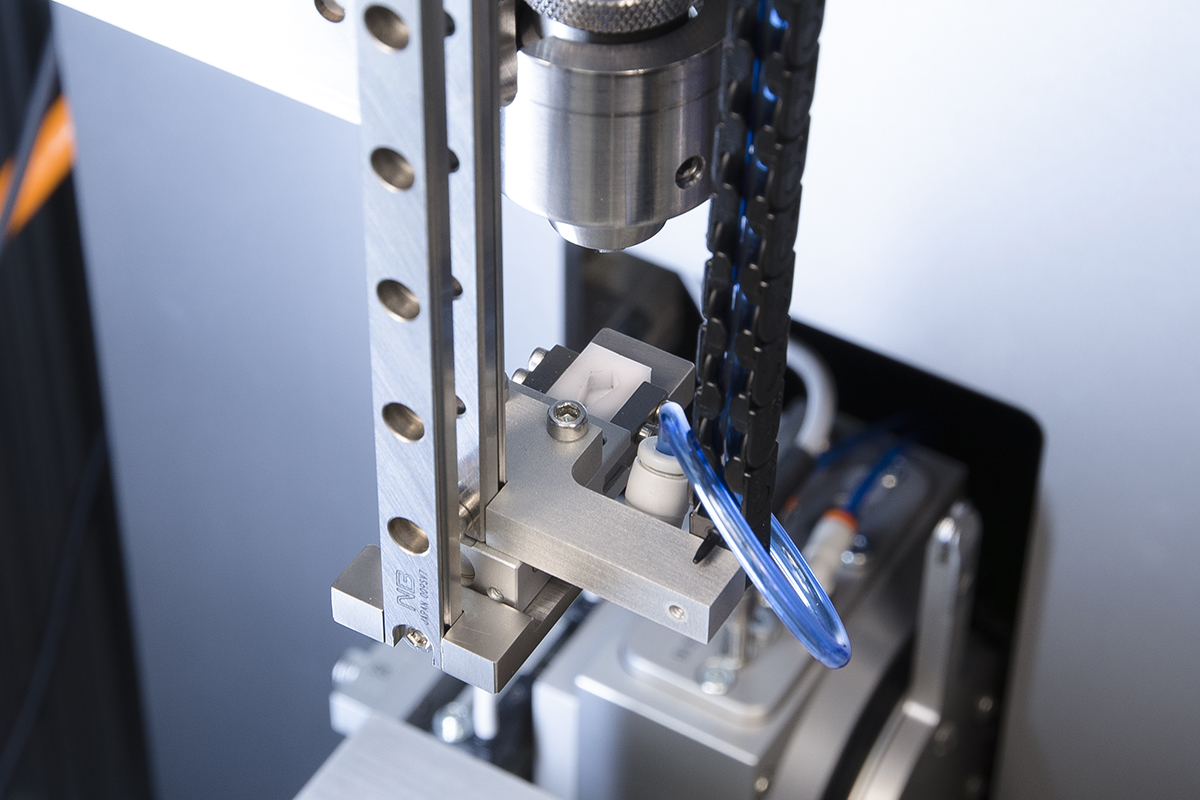

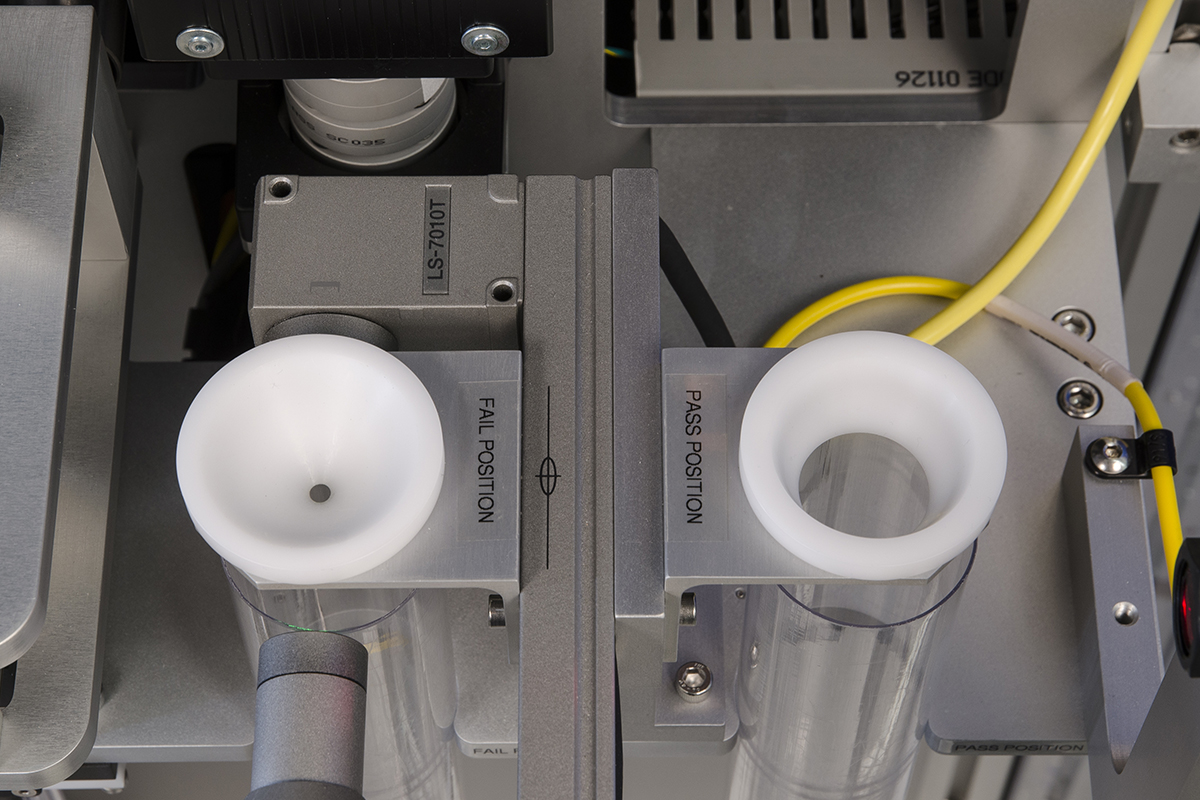

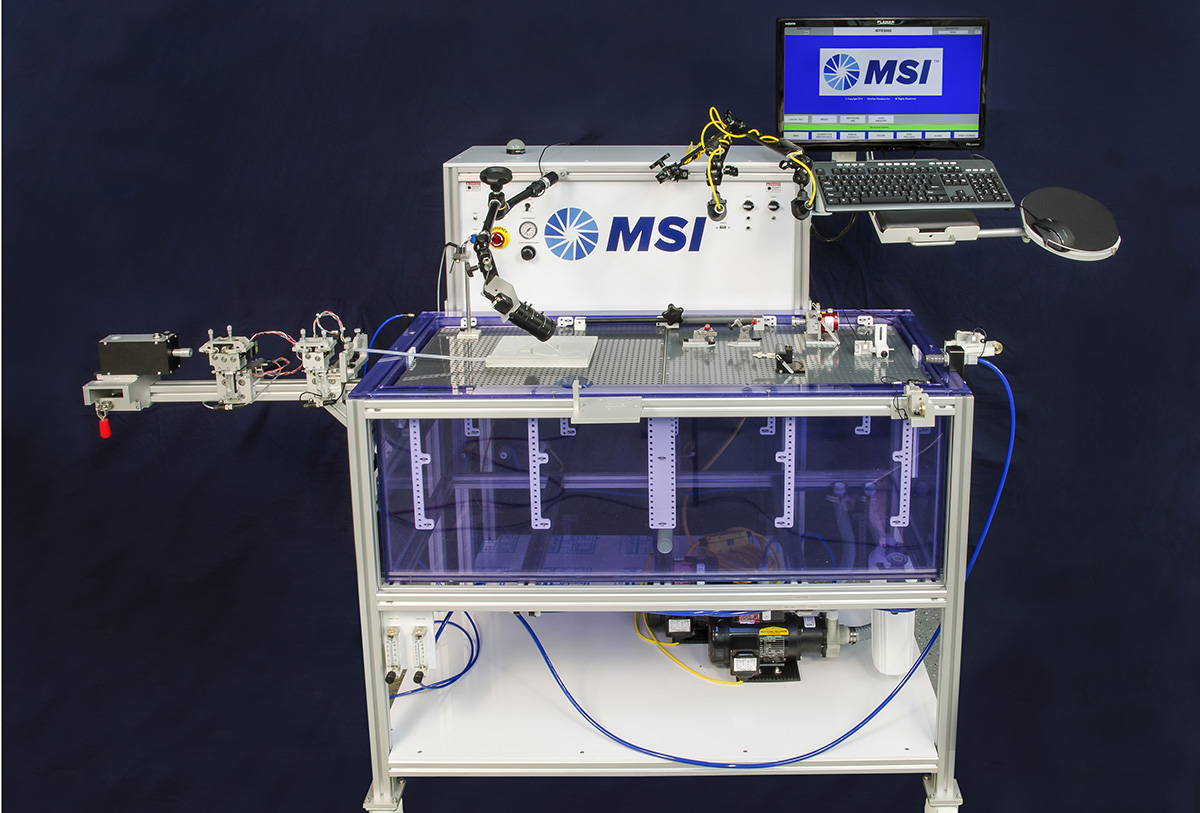

The MSI mandrel straightening equipment recycles bent or bowed mandrels through an automated straightening process. The straightener uses a pick-and-place handling system capable of picking a single mandrel from a bin, automatically running it through the straightening process, and placing it in an output tube upon completion. The MSI mandrel straightener has been configured for use with bare and coated stainless steel mandrels of various diameters and lengths with no need for tooling change.

The mandrel straightening equipment features a touch screen interface and servo motor driven motion. The PLC control system allows for easy recipe setup, product change over, and precise control of the straightening process. To set up a process, simply select a recipe, and the MSI mandrel straightener automatically configures the handling system and tooling based on the mandrel dimensions.

Product Features

- Recycle bent or bowed mandrels

- Reduce material costs

- Reduce operator dependence with automatic, pick-and-place product handling

- Process multiple mandrel diameters without tooling changes

- Process bare or coated stainless steel mandrels