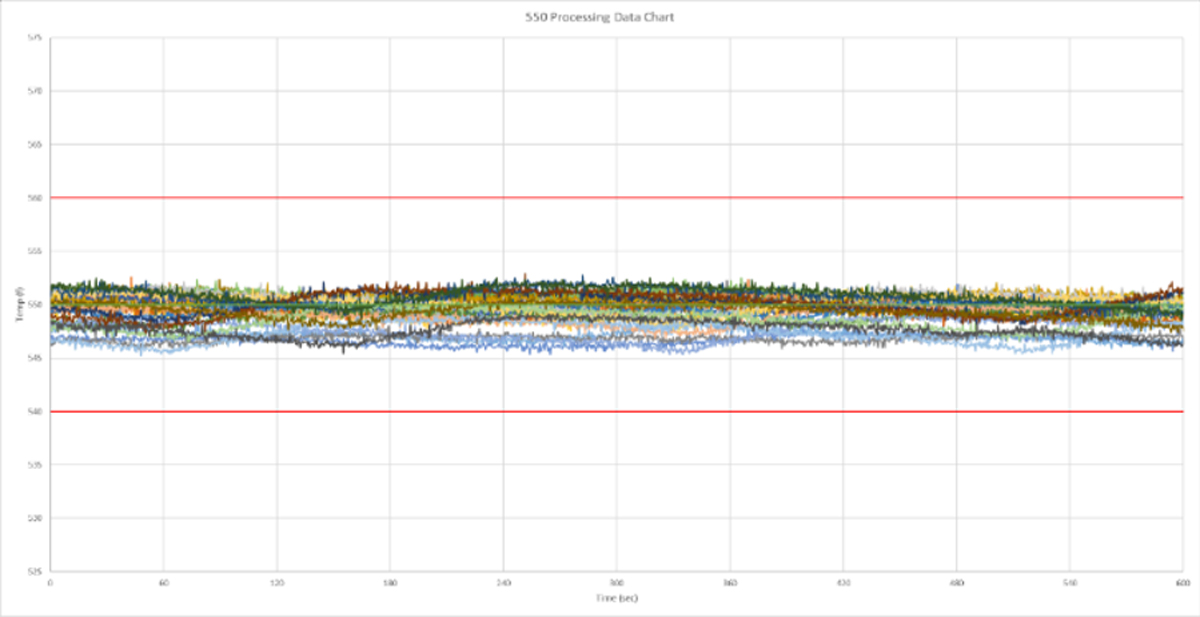

Vertical Lamination Temperature Stability & Repeatability

Design Solutions:

MSI’s VL product line design focuses on the following key areas to fill the increased market need and allow for optimal control and repeatable processing.

- Single part heater nozzle: Creating an air tight part to minimize thermal and airflow loss.

- In-line digital flow meters: The addition of in line digital airflow meters yield accurate flow rate measurements and enables the user more precise control and repeatability in setting machine parameters (HMI controlled airflow is also available)

- Industry standard PC based control system: Gives the user more control over the lamination process, higher safety standards, and ability to save multiple processing parameters and product/process recipes.

- Temperature standard fixture (optional; image right): is designed to allow unobstructed air flow while holding the thermocouple in the center most point of the nozzle to accurately record the temperature where product would experience heat.

Spec. Sheet Download

© 2025 MSI. All rights reserved. Designed and developed by: Tension Design