Catheter Lamination

Our Catheter Lamination Equipment Expertise

From “Research & Development” to “High Volume, lights out production”, Machine Solutions is your solution for Catheter Lamination.

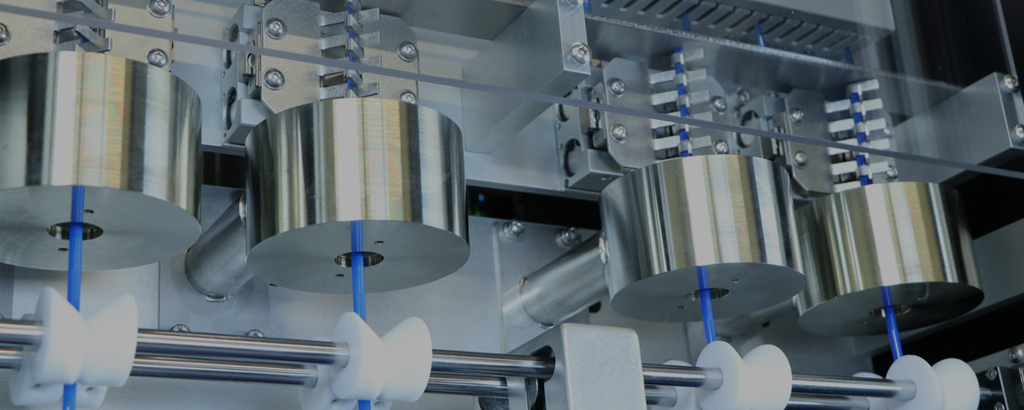

Our catheter lamination equipment provides strict parameter controls with uniform heat delivery yielding repeatable, quality results and enabling you to produce the highest quality braided catheters at the lowest effective cost. You can count on our 25+ years of reflow/lamination/heat shrink experience & expertise to give you confidence in choosing machine solutions for your application.

A team will work with you to identify the optimal system and nozzle set for your Lamination application.

Compare Laminator ModelsContact a Team MemberSolutions

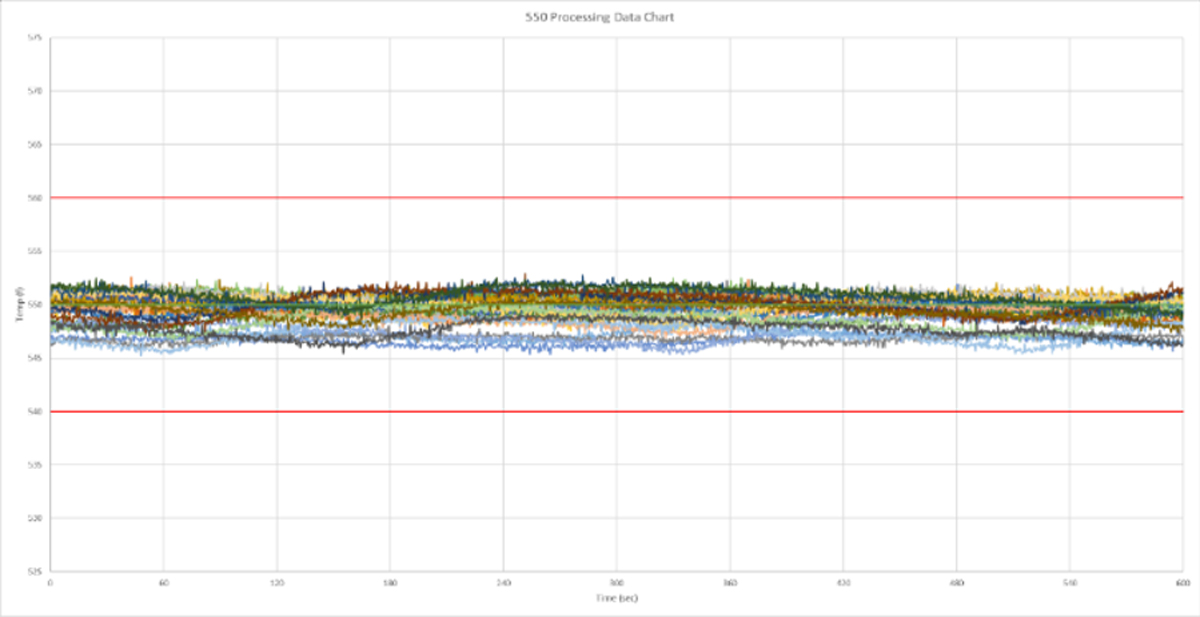

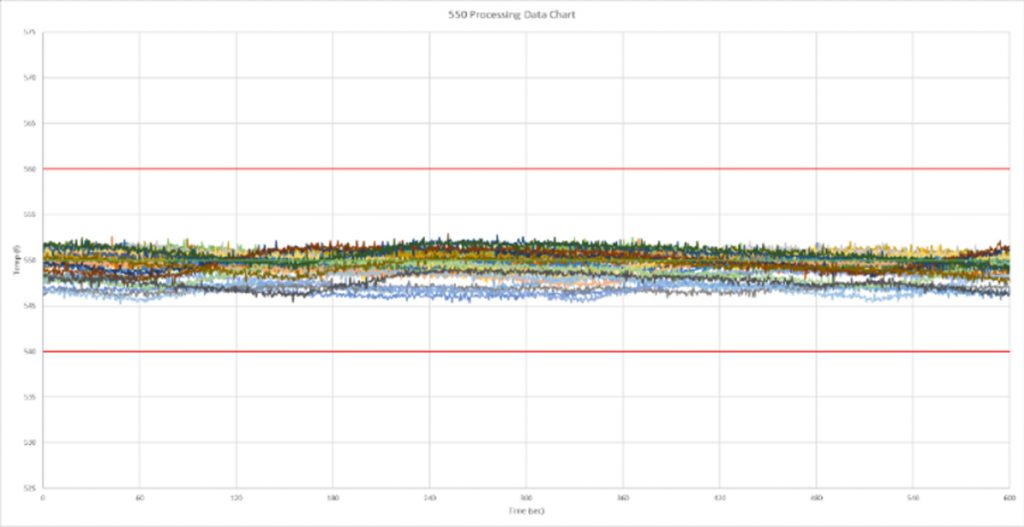

VIEW OUR VERTICAL LAMINATION TEMPERATURE STABILITY & REPEATABILITY TEST DATA

Machine Solutions conducted performance qualification testing on our catheter lamination system (VL series platform) to verify optimum consistency, stability and repeatability outputs of the equipment design. After the recommended 10-minute warm up period, testing results confirmed that lane to lane, run to run and machine to machine consistency of ±3˚F.

View the Data

How MSI Provides Superior Catheter Lamination Equipment

- Quality

- Features and Capabilities

- Ease of Use

- Proven Innovation and Expertise

- Superior Performance

Our high tolerance machining techniques using best in class materials. Equipment is manufactured at our facility and inspected for quality. We provide materials documentation and software validation, as well as support for your process validation. Our data acquisition and networking capabilities detect performance trends to enhance product performance and quality monitoring.

LEARN MORE AND DOWNLOAD OUR VERTICAL LAMINATION TEMPERATURE STABILITY & REPEATABILITY TEST DATA

Learn MoreFour (4) Station design with Six (6) programmable zones that are accurate to less than 1mm with programmable speed settings for each individual zone. Process gives the customer the option to move the nozzles down or up throughout the cycle. Unlimited profiles can be saved and recalled as needed, providing an easy setup and repeatable process. Ability to add a tensioning system to keep product centered throughout the whole process.

MSI’s laminators feature touchscreen PC operator interface designed for saving and retrieving numerous programmable parameters. Unlimited profiles can be saved and recalled as needed, providing easy setup and repeatable process, and optional tubing guides ensure product centering with each nozzle heat zone.

MSI’s PC controlled vertical shrinker’s Microswirl 360⁰™ thermal nozzle that provides uniform heating while minimizing hot or cold spots during the shrinking process, providing superior results to flat or “c” nozzle technologies.

With a four station design and six programmable zones accurate to less than 1mm and programmable speed setting for each individual zone, the MSI Catheter Laminating process is unparalleled in the market. Our innovative laminating technique and precision controls result in even lamination without the longitudinal elongation seen in ovens.

Dual Array Lamination Solutions

Dual Array Lamination Solutions  RadiantPro Radiant Heat Vertical Lamination System

RadiantPro Radiant Heat Vertical Lamination System  Horizontal Laminator

Horizontal Laminator  4-up Catheter Laminating Machine (810A)

4-up Catheter Laminating Machine (810A)  Vertical Lamination Temperature Stability & Repeatability

Vertical Lamination Temperature Stability & Repeatability  VL400/VL1000 Catheter Reflow Machine

VL400/VL1000 Catheter Reflow Machine