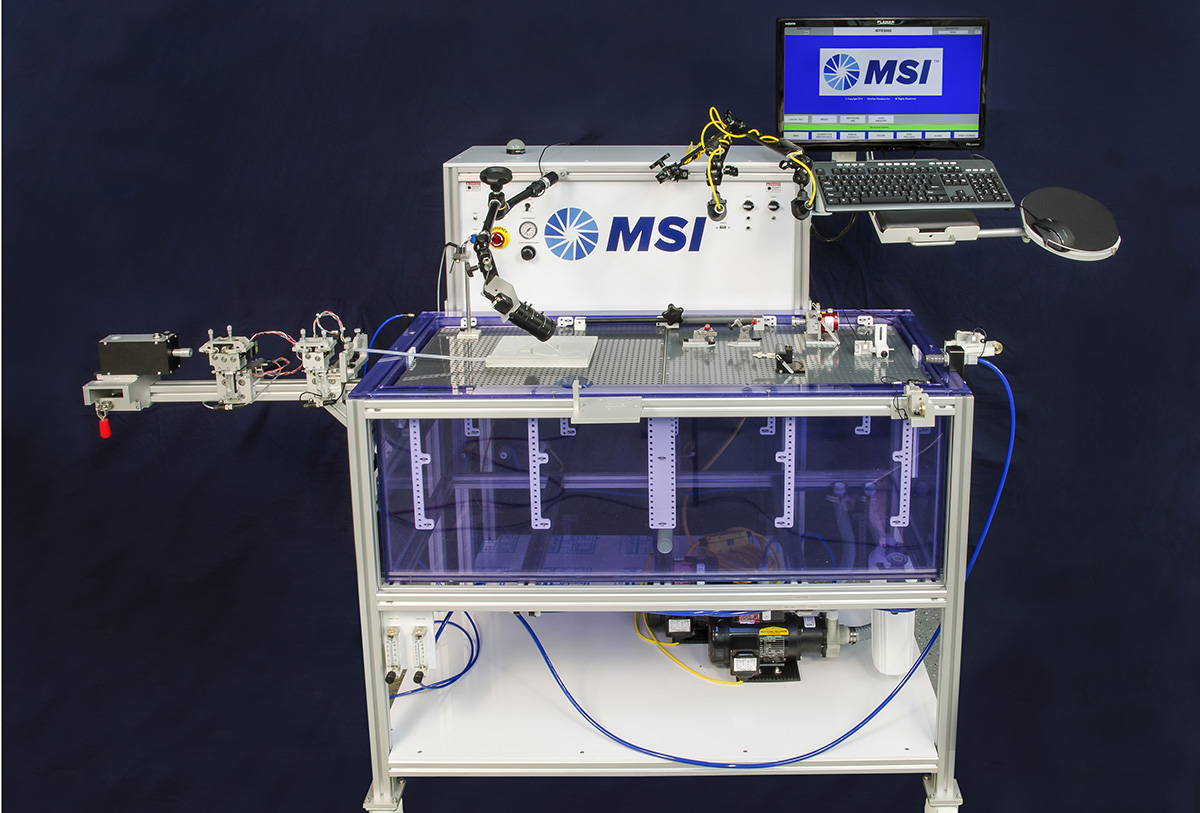

Mandrel Straightening

Product Features

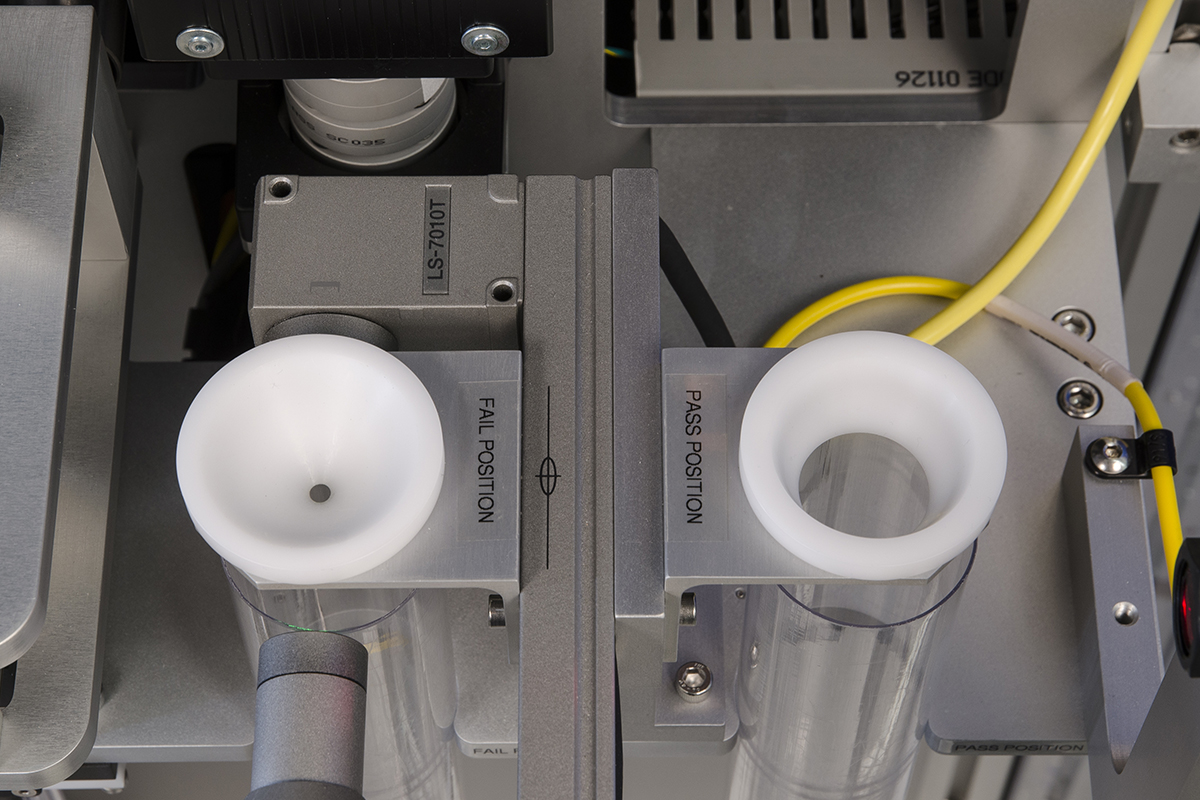

- Recycle bent or bowed mandrels

- Reduce material costs

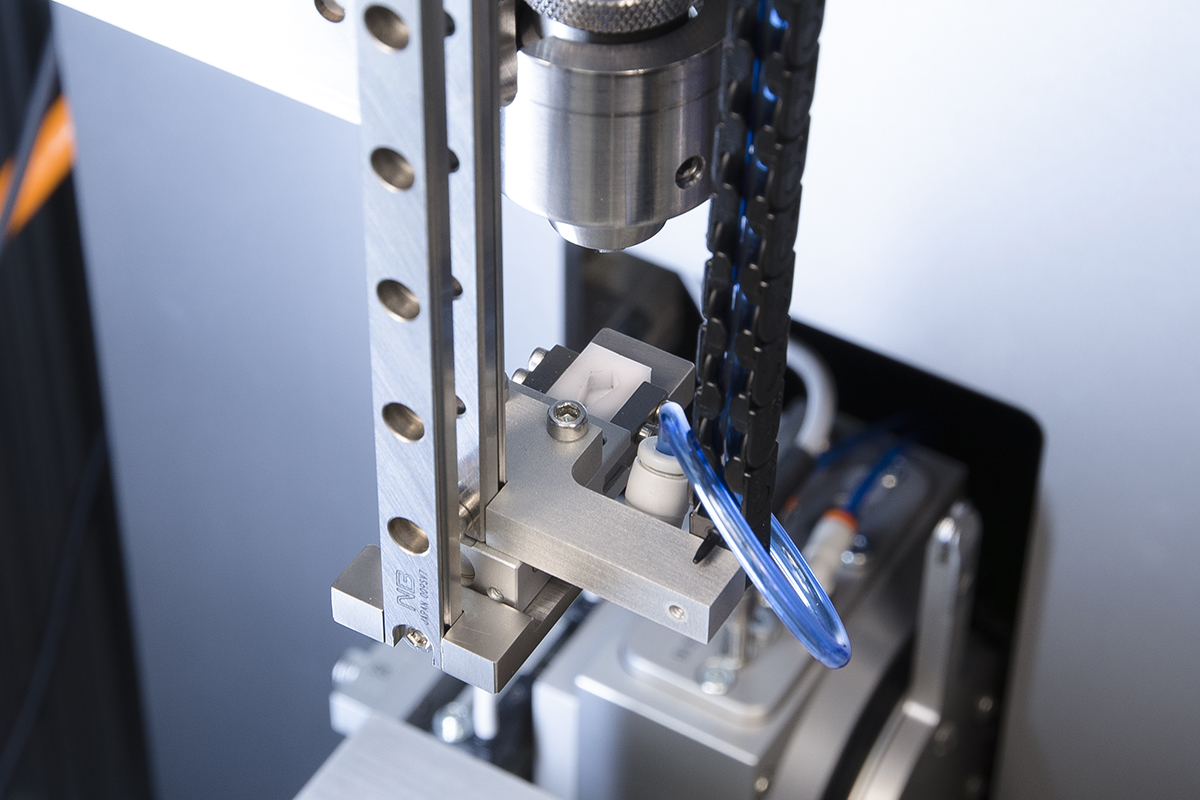

- Reduce operator dependence with automatic, pick-and-place product handling

- Process multiple mandrel diameters without tooling changes

- Process bare or coated stainless steel mandrels

Spec. Sheet Download

© 2025 MSI. All rights reserved. Designed and developed by: Tension Design