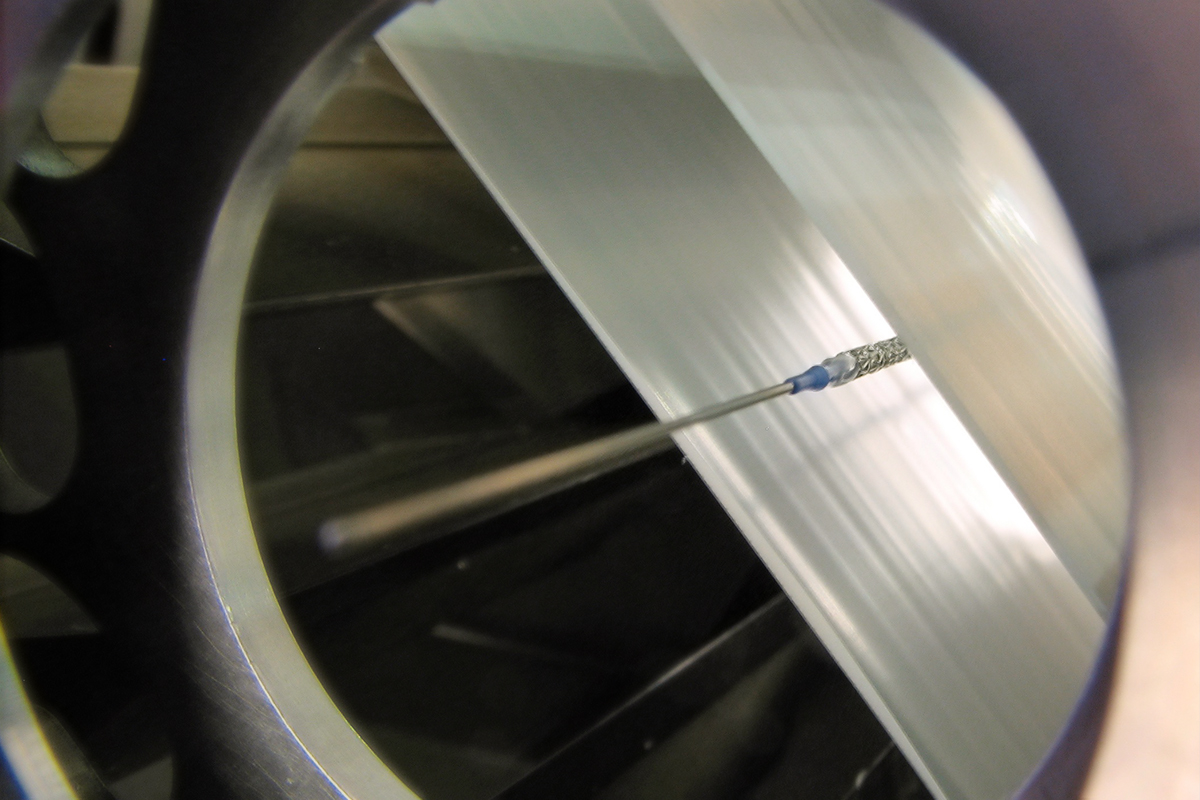

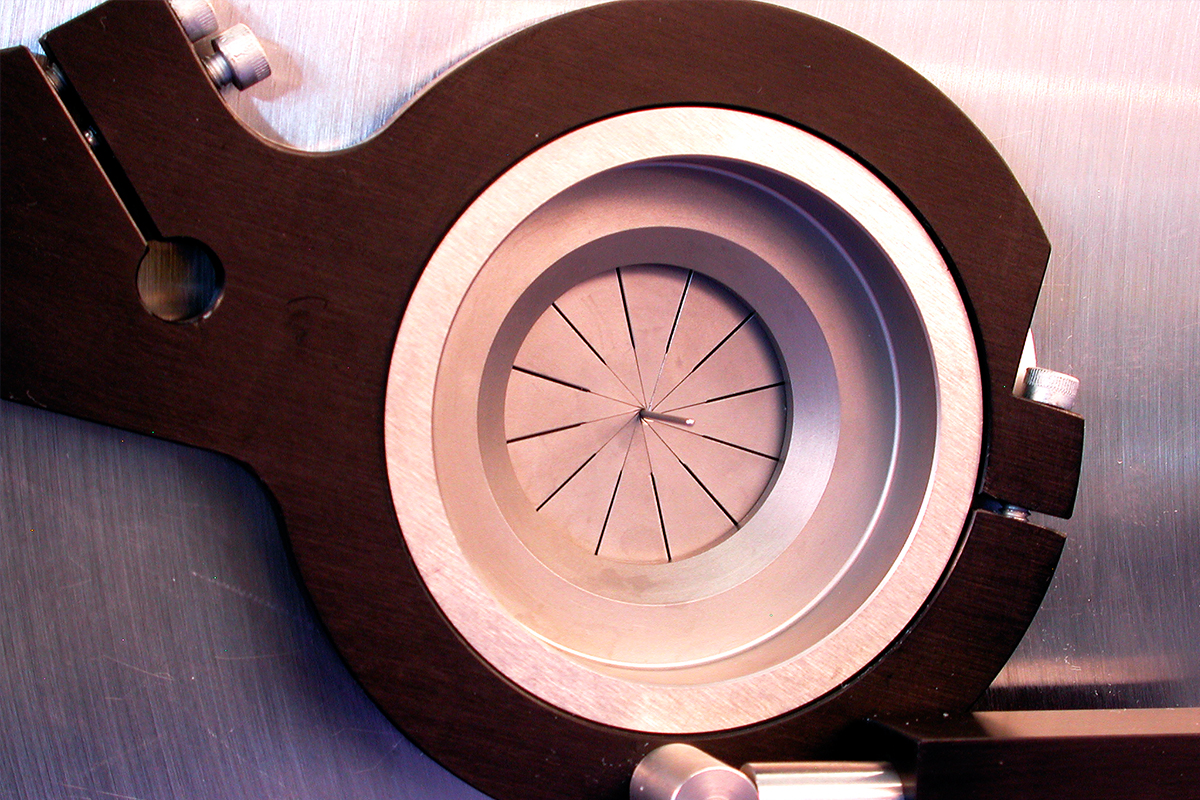

Drug Coated Stent Crimping

PRODUCT FEATURES

- Protects drug coatings and surface of polymer scaffolds

- Significantly reduces cycle time

- Ensures uniform compression to eliminate strut overlaps

- Allows for fast loading of product with wide film spacing

- Integrates heat and balloon inflation to optimize stent securement

- Supports optional features such as barcode scanning, leak detection, and laser micrometer

Spec. Sheet Download

© 2025 MSI. All rights reserved. Designed and developed by: Tension Design