Hydraulic Burst Leak Testing

Crescent Design – World Leaders in Hydraulic Burst Leak Testing

Whether your testing catheters, balloons, tubing, fittings, or valves, The Crescent Design HBLT™ Hydraulic Burst Leak Tester is the only choice for hydraulic pressure testing.

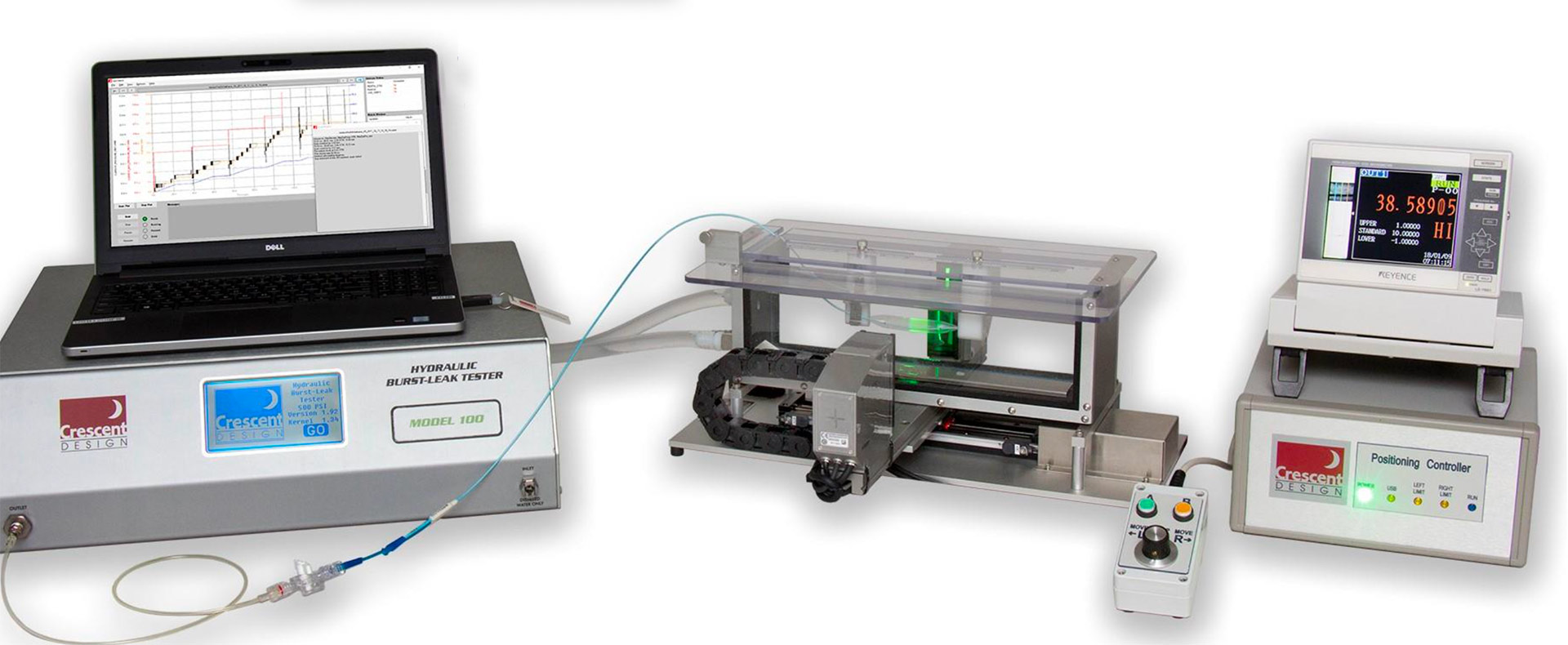

The HBLT™ Hydraulic Burst Leak Tester is available is 8 different models with maximum pressure ranging from 25 – 5000 psi. This tabletop, computer-controlled device delivers pressurized distilled water during precisely controlled, repeatable tests. The HBLT™ Tester has been in production since 1994 and has become the world -wide quality standard for hydraulically testing a wide range of devices. It is the medical industry’s #1 choice for all ISO 10555 testing, AQL testing, and R&D testing needs.

Crescent Design’s Balloon Compliance Test Fixture (CTF) uses a standard, low-force Mitutoyo Digimatic gauge for taking contact diameter measurements or a Keyence LS Optical Micrometers for non-contact diameter measurements to meet balloon compliance testing requirements such as ISO 25539, ISO10555 or FDA-1545.

Our team will work with you to identify the best HBLT™ Hydraulic Burst Leak Tester to meet your testing needs.

Compare HBLT™ Tester ModelsHydraulic vs. Pneumatic TestingContact a Team Member| Model | Max Pressure | Max Volume | Accuracy | Resolution |

|---|---|---|---|---|

| 25, 25 X, V25 LH | 25 PSI /1.7 ATM / 1.7 BAR | 68CC, 184CC, 1200CC | +/-0.25 PSI | 0.1 PSI |

| 100, 100 XV, 100 LH | 100 PSI / 6.8 ATM / 6.9 BAR | 68CC, 184CC, 1200CC | +/-0.5 PSI | 0.1 PSI |

| 250,250 XV | 250 PSI / 17 ATM / 17 BAR | 68CC, 184CC | +/-1.0 PSI | 0.5 PSI |

| 500, 500 XV | 500 PSI/ 34 ATM / 34 BAR | 68CC, 184CC | +/- 2.0 PSI | 0.5 PSI |

| 1000, 1000 XV | 1000 PSI / 68 ATM / 69 BAR | 42CC, 106CC | +/-4.0 PSI | 1 PSI |

| 2000, 2000 XV | 2000 PSI / 136 ATM / 138 BAR | 26CC, 62CC | +/-8.0 PSI | 1 PSI |

| 3000, 3000 XV | 3000 PSI / 204 ATM / 206 BAR | 10CC, 24CC | +/-8.0 PSI | 1 PSI |

| 5000, 5000 XV | 5000 PSI / 340 ATM / 344 BAR | 10CC, 24CC | +/-12.0 PSI | 1 PSI |

- HBLT™

- Smart Manifold

- Vacuum Purge Adaptor (VPA)

- Balloon Compliance

- Pressure Manager

- Liquid Based Pressure Testing

HBLT™ Hydraulic Burst Leak Tester

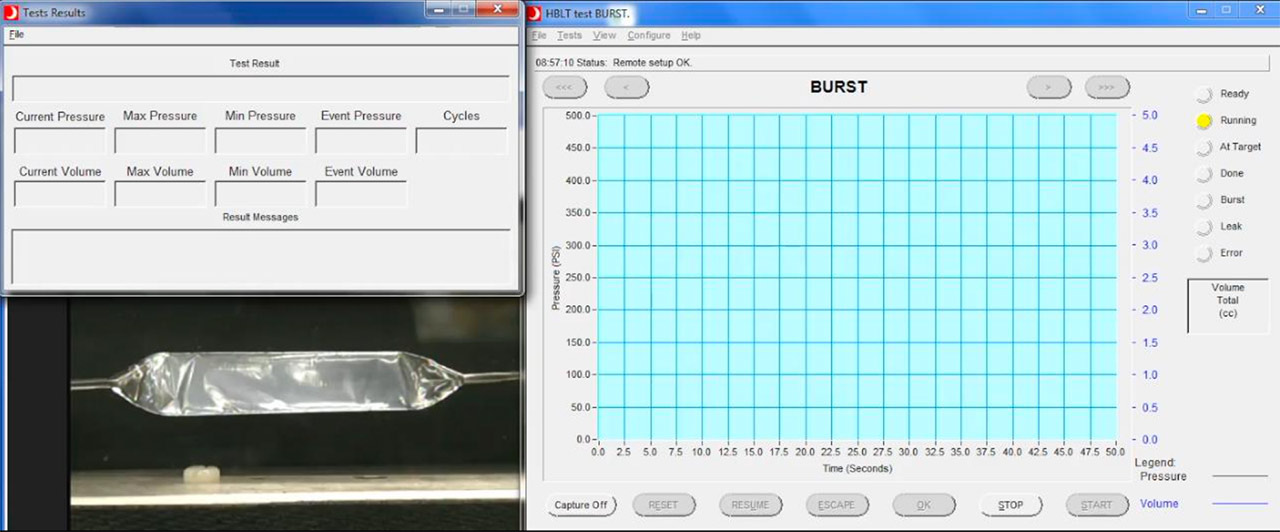

Machine Solutions offers a sophisticated system for destructive and nondestructive hydraulic (distilled water) pressure testing angioplasty balloons as well as other medical devices

- Vacuum to 5000 PSI Capability

- Compact Design

- Backlit LCD Touch Screen

- Programmable Test Profiles

- Printer Interface

- Field Upgradable Software

- Built in Networking

- Test Import/Export with other HBLT’s

- Cover-on Self Pressurizing Calibration

- Total Loss Distilled Water System

- Selectable Pressure Display Units

- Plastic Tubing

- IV Bags

- Fitting to tubing bonds

- Cannulas

- Check valves

- Programmable Pressure Source

Smart Manifold – Increase your testing thru-put 10 times

The more you can automate the more you can save, and that’s what our Smart Manifold helps you to do.

Connect our Smart Manifold to our HBLT Hydraulic Burst Leak Tester and you can do unattended testing of one to ten parts simultaneously. With three basic testing modes to choose from, the Smart Manifold lets you pressurize all selected ports simultaneously, or pressurize each selected port individually, or pressurize only one port at a time. Plus, you can add our Pressure Manager© Windows-based program to your system to operate the HBLT Tester by remote control and to program tests that ordinarily couldn’t be done with just the HBLT alone.\

So, if you’re looking for an easy, cost-effective way to automate your testing capabilities, connect the Smart Manifold to your HBLT Tester.

Vacuum Purge Adapter – Automated Catheter Prepping

The Vacuum Purge Adapter (VPA) is another piece in the puzzle for completely automating burst and leak testing with the HBLT. When interfaced with the HBLT Tester and Smart Manifold, the VPA allows for the fully automatic purging/prepping of catheters. The VPA employs a powerful vacuum pump to remove air from the attached product, readying the product for hydraulic testing. The need to manually prep the catheters with a syringe is eliminated.

Features include:

- User programmable vacuum to greater than -13 psi (-26 in/Hg)

- Two user programmable timers for vacuum duration

- Selectable ports allowing for automatic prep and test of one to ten samples

Increased throughput

- Eliminates the need for manually prepping catheters with a syringe

- Catheters can be deflated at the end of a test, if desired

- Increased throughput

- Eliminates the need for manually prepping catheters with a syringe

- Catheters can be deflated at the end of a test, if desired

Balloon Compliance Testing

Contact and Non-Contact, Single and Multi-point Measurement

Balloon compliance testing compares balloon pressure to resulting balloon diameter across a full range of pressure up to 25% above rates burst pressure. Our Balloon Compliance Test Fixture (CTF) allows for the automatic contact measurement of products while submerged in a water bath. A standard, low-force Mitutoyo Digimatic gauge is mounted on an adjustable stand that will accommodate water baths of various depths. The Balloon Compliance Test fixturing was designed to accommodate a wide range of balloon product types and sizes and all components are corrosion resistant.

Crescent Design’s non-contact, single point diameter measurement systems employ a Keyence Optical Micrometer mounted to a temperature-controlled water bath with specially designed product fixturing.

The Positioning Controller system offers non-contact, multi-point diameter measurement readings during balloon compliance testing. The Positioning Controller consists of a water bath and Keyence LS7070 micrometer mounted to a translation stage that allows the micrometer to be positioned horizontally. It is available with a 14-inch bath (8 inches of travel) or a 20-inch bath (14 inches of travel).

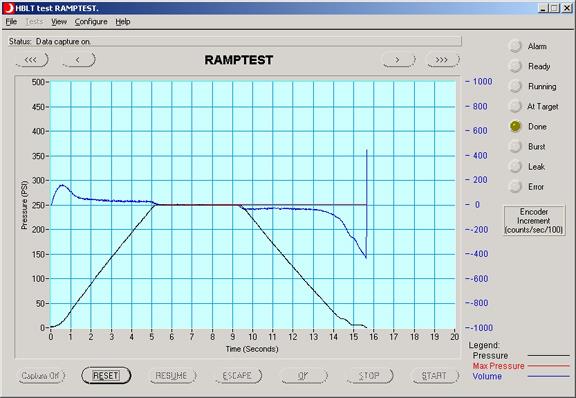

Pressure Manager© is a Windows® based program that can manage the setup, operation and data collection of the Crescent Design HBLT Hydraulic Burst Leak Tester. The program allows a user to quickly enter, edit and run tests or scripts. While executing a test or script, Pressure Manager© displays a graph of the current pressure, maximum pressure, and one of four volume traces. In addition, Pressure Manager allows the user to save the data collected for later analysis or graphing.

Pressure Manager provides these four primary advantages over standalone HBLT operations.

- Provides both speed and ease of operation The Windows interface is familiar and provides quicker data entry and operational control.

- Graphs provide more information about the behavior of the product during the test. The operator can detect evidence of product compliance or leaks prior to their detection by the HBLT Tester.

- Collects the data for future detailed analysis. The data is saved in a form that most graphing and analysis programs can import.

- Provides custom scripting capabilities. This allows the operator to design a test specific to a product. The scripting also allows use of the volume control commands that are not available from the HBLT Tester alone.

The HBLT™ Tester, a hydraulic pressure tester, is an ideal choice for testing products that involve the use of liquids. Its versatility extends beyond balloon catheter testing, as it can be employed to evaluate a wide range of medical devices. HBLT Tester equipment serves as a programmable pressure source, catering to any application that requires liquid-based pressure testing data.

Furthermore, this equipment has broader applications that extend across different divisions and teams. It proves valuable for research and development, aiding in the development of new products. Quality control teams can rely on it for design assurance and AQL testing. Additionally, marketing teams can utilize it for comparative testing data, making it a valuable asset in various aspects of the medical device industry.

IV Sets

- The HBLT™ Tester is used to test the individual parts including the drip chamber, fittings, and tubing or the entire set up.

Check Valves

- The HBLT™ Tester is used to ensure the valves function as expected with no leaks.

Inline filters, Blood filter systems, IV bag testing

- The HBLT™ Tester is used to Pressure test filters and IV bag systems.

Needleless injection sites, Stopcocks

- The HBLT™ Tester is used to identify cracking pressure, leak testing, burst testing.

Let’s Discuss You Application Needs

Contract Testing and Product Characterization Services

The Machine Solutions Lab in Flagstaff is equipped with a full HBLT™ Tester system that can be used to provide contract testing and product characterization services. We also welcome customers to visit our lab and use the HBLT™ Tester.

- ISO 10555 – 1, Annex C and F

- ISO 10555 – 4, Annex A, B, and D

- ISO 11070, Annex D and E

- ISO 80369 – 3 – 6.2.2

- ISO594–1and2-594-1 -5.2and594-2–5.2

*Crescent, Crescent Design, HBLT and logos (or designs) are trademarks of Crescent Design, Inc. or its affiliates.