Balloon Catheter Pleating and Folding

Drug-Coated Balloon Catheter Pleating and FoldingProtect drug coatings from damage and cross contamination

Choose a trusted technology to produce superior performing balloon catheters

Superior Performance

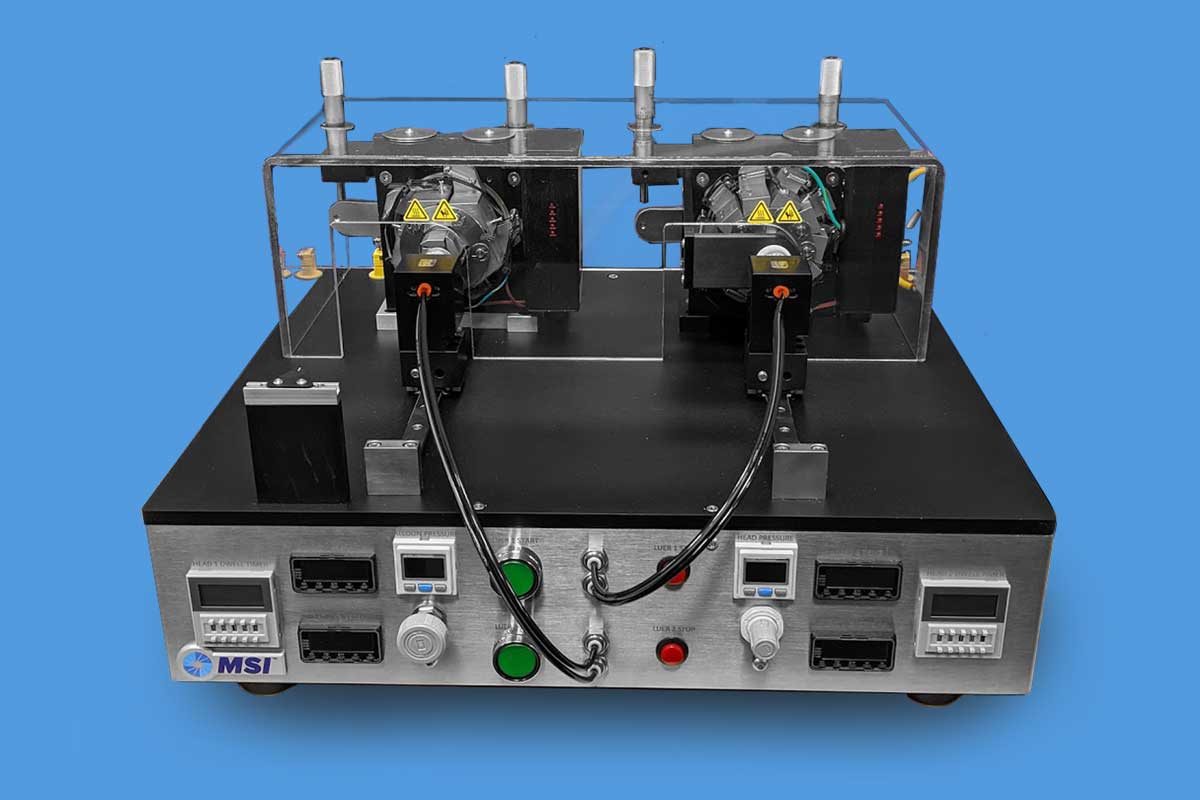

Our patented Wavepleat™ design reduces cycle times and minimizes fold diameters by optimizing curvature for the balloon material. Uniform pleat lengths ensure equal deployment forces in vivo and maximizes successful rewrap after deployment. . MSI equipment meets the highest dimensional and temperature tolerances in the industry to support high yields and product safety. We custom-design every machine to optimize the customer’s production process.

Proven Innovation and Expertise

MSI’s revolutionary folding method and equipment is used to manufacture most approved balloon catheters on the market today. MSI has installed hundreds of machines throughout the last decade. They are used to fold every size balloon catheter available. We are the process, product, and equipment design experts, and we offer free sample processing to prove capability prior to purchase.

Ease of Use

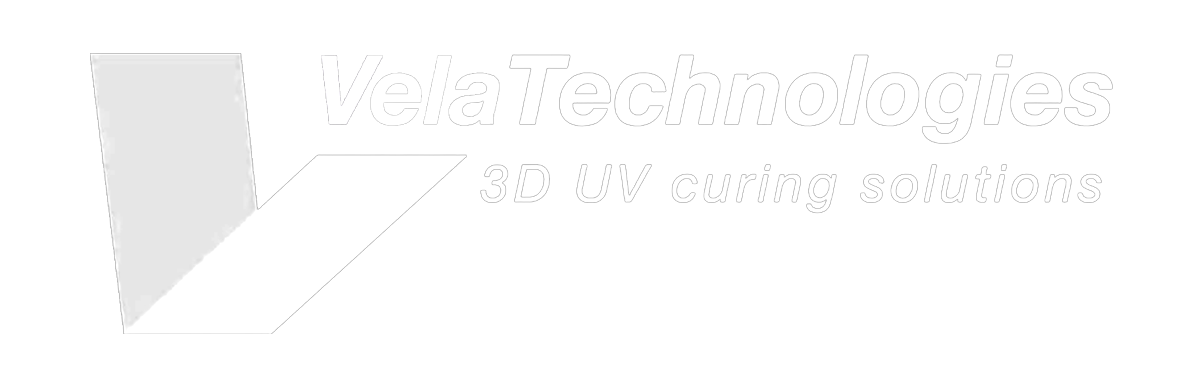

MSI designs equipment for usability and versatility. Users can calibrate MSI machines using the built-in software functions, and can remove and replace the pleat and fold heads without returning the machines to the manufacturer. Process limits prevent product damage and automation options limit operator interaction and product handling, reducing operator dependency.

Features and Capabilities

Through MSI, you can purchase proven technology at an entry-level price point and add automation features to accommodate high-volume manufacturing. Automation platforms increase throughput, improve yields, reduce cycle time, and reduce cost. Barcode scanning and recipe storage options provide fast and secure process parameter selection. Recipe parameters are controlled by a fully integrate PLC, ensuring process accuracy and data security.

Quality

At MSI, we hold ourselves to a high standard of quality assurance. We use best-in-class materials and manufacture our proprietary designs in-house to ensure complete control. Quality documentation is provided with every product, with optional support for software validation and process validation. MSI machines can help support your quality control system with optional data acquisition and networking capability for detecting and tracking performance trends. MSI machines are CE marked.

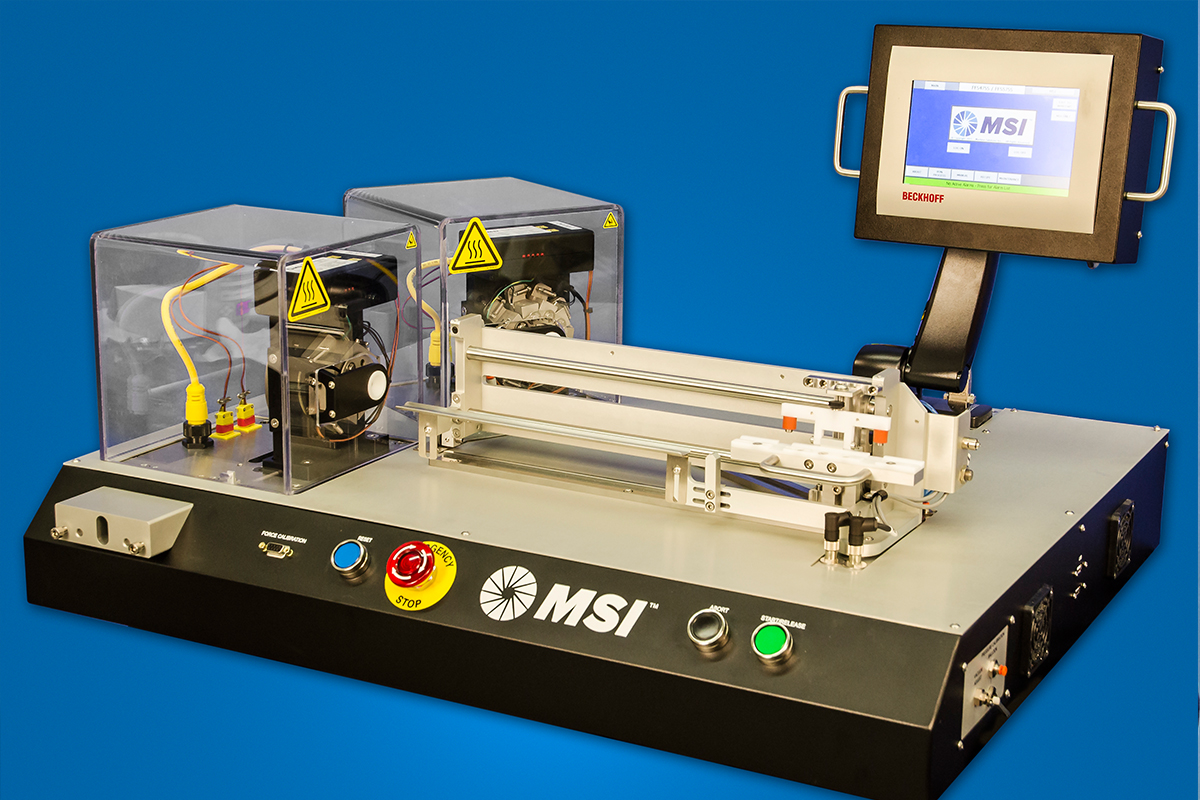

Drug Coated Balloons

Drug-eluting balloon technology presents its own manufacturing challenges. MSI offers a specialized machine base for pleating and folding coated products. This design integrates Teflon film to protect coatings on the balloon’s surface while achieving the uniform pleating manufacturers rely on. Available automation features ensure high production yields and significantly reduce cycle times.