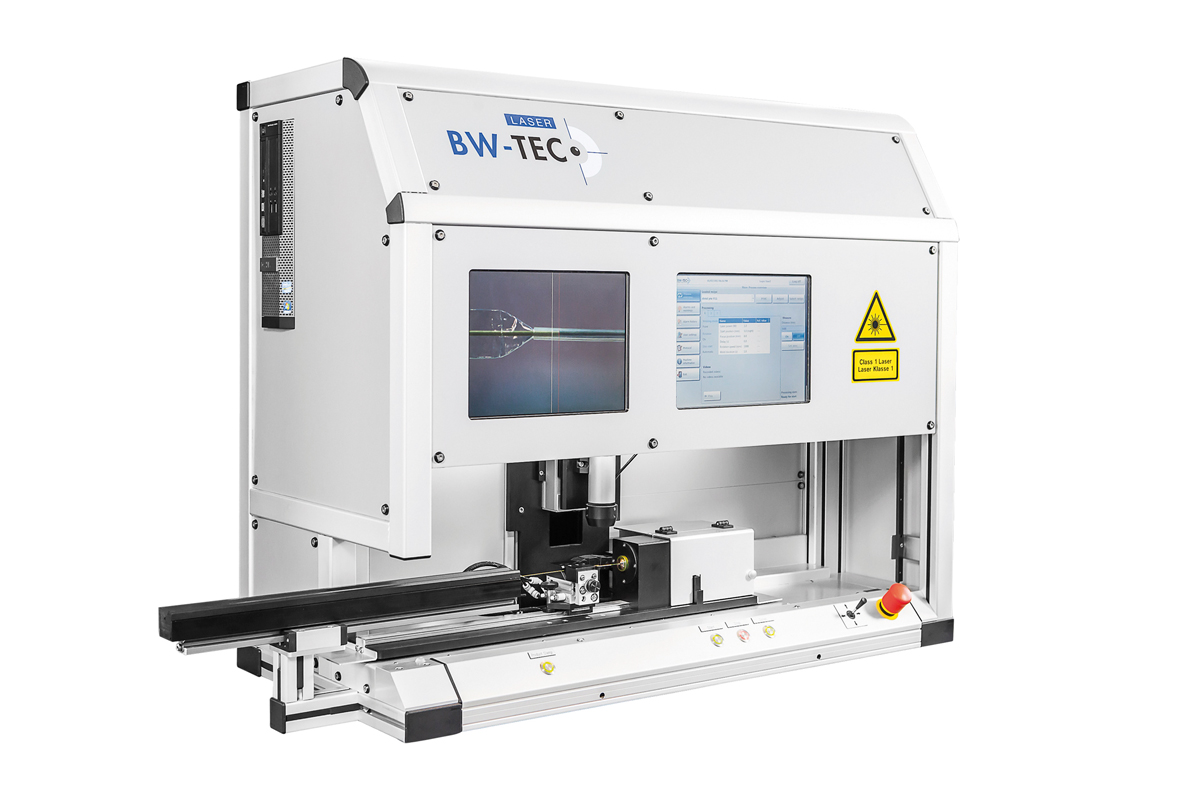

Laser Bonding Equipment

Laser bonding equipment provides our customers with the greatest value

Superior Performance

Laser bonding is an efficient method for safe and effective joining of PTCA devices. MSI’s laser bonding equipment provides leak-proof bonding with user-controls to adjust CO2 laser wattage and bond site temperature. This technology promotes smooth, seamless, and flexible joints between technologically advanced designs and materials.

Proven Innovation and Expertise

MSI’s innovative, servo motor-controlled handling system makes its laser bonding equipment versatile enough to use for a variety of applications, including proximal and distal balloon bonds, soft tip attachment, and many other catheter and tube bonding processes.

Ease of Use

MSI equipment is user friendly. It features drop-in, top-loading rotational product handling, barcode scanning, integrated vision assist, and jog controls to facilitate device manufacturing. MSI even offers an optional automated product alignment system. MSI’s laser bonder also incorporates a 19” touch screen PC interface that can be used for easy, step-by-step profile programming.

Features and Capabilities

MSI’s laser bonding equipment uses a 30 watt, 10.6μm wavelength CO2 laser. The beam width is user-adjustable and applied in a column shape to ensure constant product contact, even with bent mandrels. The application of the CO2 laser to thin PTCA materials ensures uniform, consistent bonding with low energy consumption.

MSI offers high-accuracy controls, including a closed loop power sensor to control laser wattage, and a closed loop infrared temperature sensor to control the bond site temperature. For process controls, the PLC control system features unlimited profile storage capacity and multilevel password protection. The data acquisition feature allows the user to access process data in both graphical and Excel file formats.

Our laser bonding equipment also features a fully enclosed, shielded machine bae designed and built for user safety.

Quality

Our high tolerance machining techniques using best in class materials. Equipment is manufactured at our facility and inspected for quality. We provide materials documentation and software validation, as well as support for your process validation. Our data acquisition and networking capabilities detect performance trends to enhance product performance and quality monitoring. CE mark.