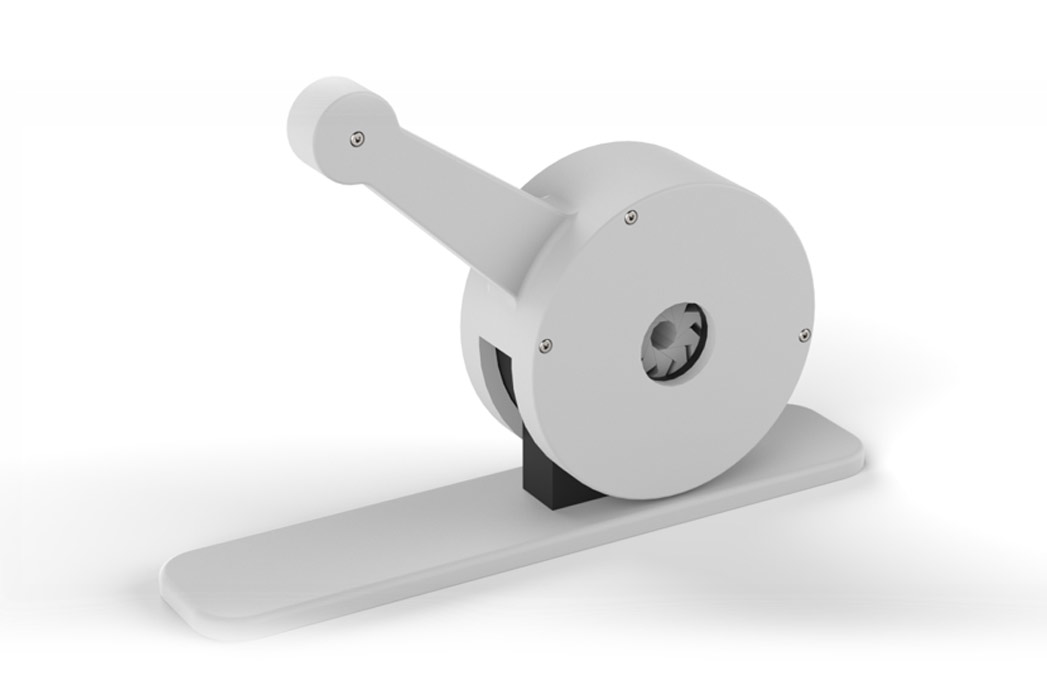

HV1000 Disposable Heart Valve Crimping Tool

HV1000 Features

- Even, repeatable radial compression.

- Single person operation.

- Small footprint for lab/bedside applications

- Low cost, disposable, single procedure tool.

- Over 200N radial force

- Hybrid segment and cam path design

HV1000 Tool Specifications

- Machined designs and Injection molded options

- Ten segment design.

- Diameter range 3mm-38mm, and custom ranges.

- Element length 40mm and custom.

- Designed for single use.

- Equipment supplied bulk, non-sterile.

- Machined prototypes for multi-use product development

© 2026 MSI. All rights reserved. Designed and developed by: Tension Design