Stent Securement Testing

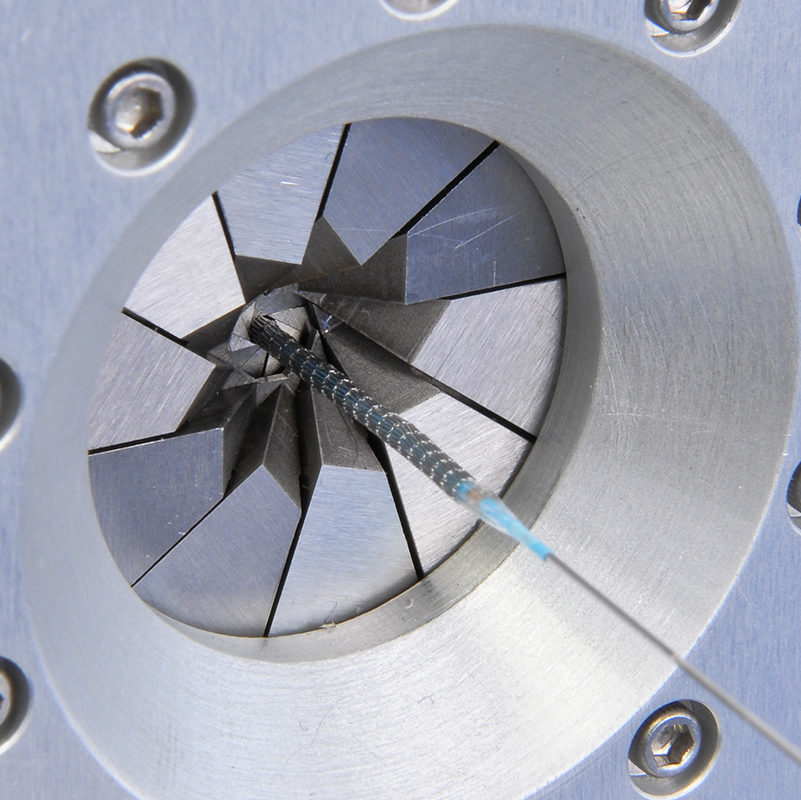

Stent securement testing equipment measures and records the force required to dislodge a balloon-expandable stent from its position on a balloon. The stent securement tester functions as a standalone unit with an optional submersible configuration for testing in an aqueous, temperature-controlled environment. The mechanical device in the stent retention tester is a dual-sectioned, segmental head. One section radially grips the balloon while the second captures the stent edge. These head sections separate to dislodge the stent proximally or distally from the balloon. The stent retention and securement testing equipment is controlled by Windows PC-based software. Its adjustable testing parameters include head close speed, capture diameter, capture maximum force, gripper force, pull speed, and pull distance. The software measures, displays, graphs, and writes force and distance data to a CSV file for easy analysis.Why MSI leads in stent retention and securement testing

Superior Performance

Proven Innovation and Expertise

Ease of Use

Features and Capabilities

Stent securement base:

Control module specifications:

Software specifications: