Stent Crimping

MSI equipment has crimped most of the balloon expandable stents used in the world

Superior Performance

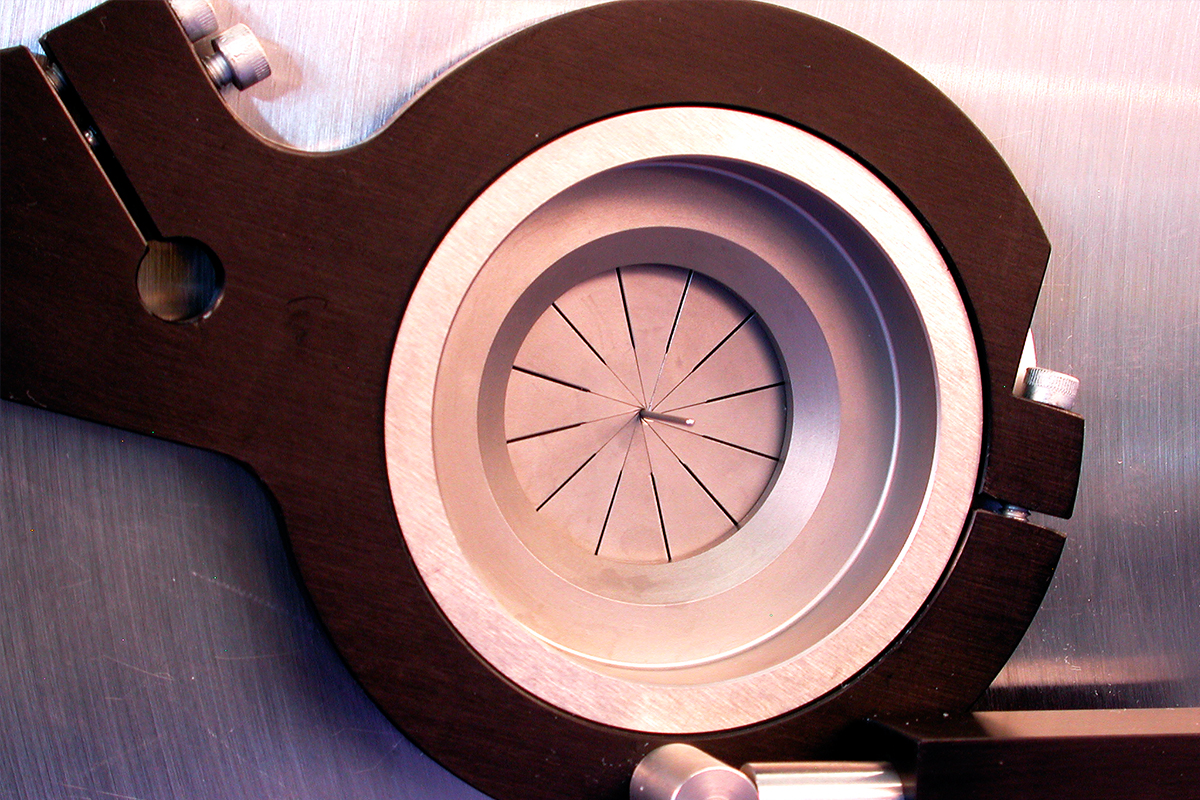

MSI’s stent crimping equipment is the industry standard for crimping bare metal stents, drug eluting stents, and next-generation polymer scaffolds. MSI offers a complete range of stent crimpers suitable for all your requirements, from R & D through high-volume manufacturing. Our equipment optimizes stent securement, crimp profile, and circumferential uniformity, and helps our customers produce the best stent delivery systems in the world.

Proven Innovation and Expertise

MSI is the original inventor of revolutionary stent crimping techniques. Our equipment is used to manufacture most approved stents and scaffolds on the market today. We have been successfully designing and manufacturing stent crimping solutions for over 14 years with successful installation at over 150 facilities around the world. MSI’s development team supports the changing needs of our customers with machines that are customized for their processes.

Ease of Use

MSI equipment is process-focused and emphasizes repeatability. Our production stent crimping machines feature robust PLC control systems that automate repetitive steps with minimal operator dependency. Fast, secure process parameter selection through barcode scan and recipe storage ensures that your processes are controlled for every product variety. R & D equipment, including our hand-held and hand-operated crimpers, emphasizes user control.

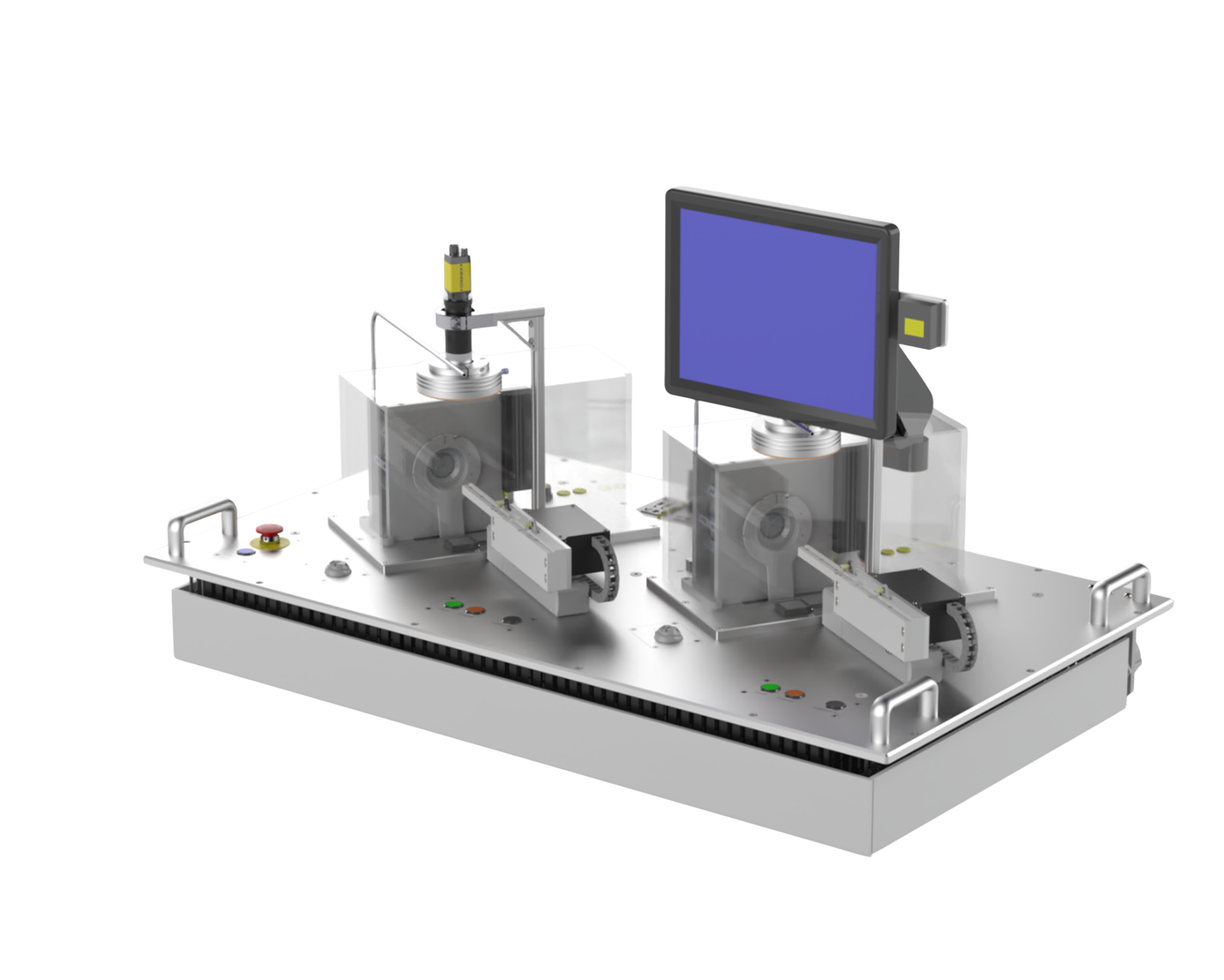

Features and Capabilities

MSI offers proven technology at an entry-level price point with optional automation upgrades to accommodate high-volume manufacturing. Automation platforms increase throughput, improve yields, reduce cycle time, and reduce cost. MSI’s specialty equipment automatically positions, crimps, and inspects stents in a single work station.

Quality

MSI ensures the precision of our customers’ processes by using best-in-class materials and equipment to produce our machines. MSI also offers support for customer validation by providing quality inspection reports and software verification documentation. MSI machines can help support your quality control system with optional data acquisition and networking capability for detecting and tracking performance trends. MSI machines are CE marked.

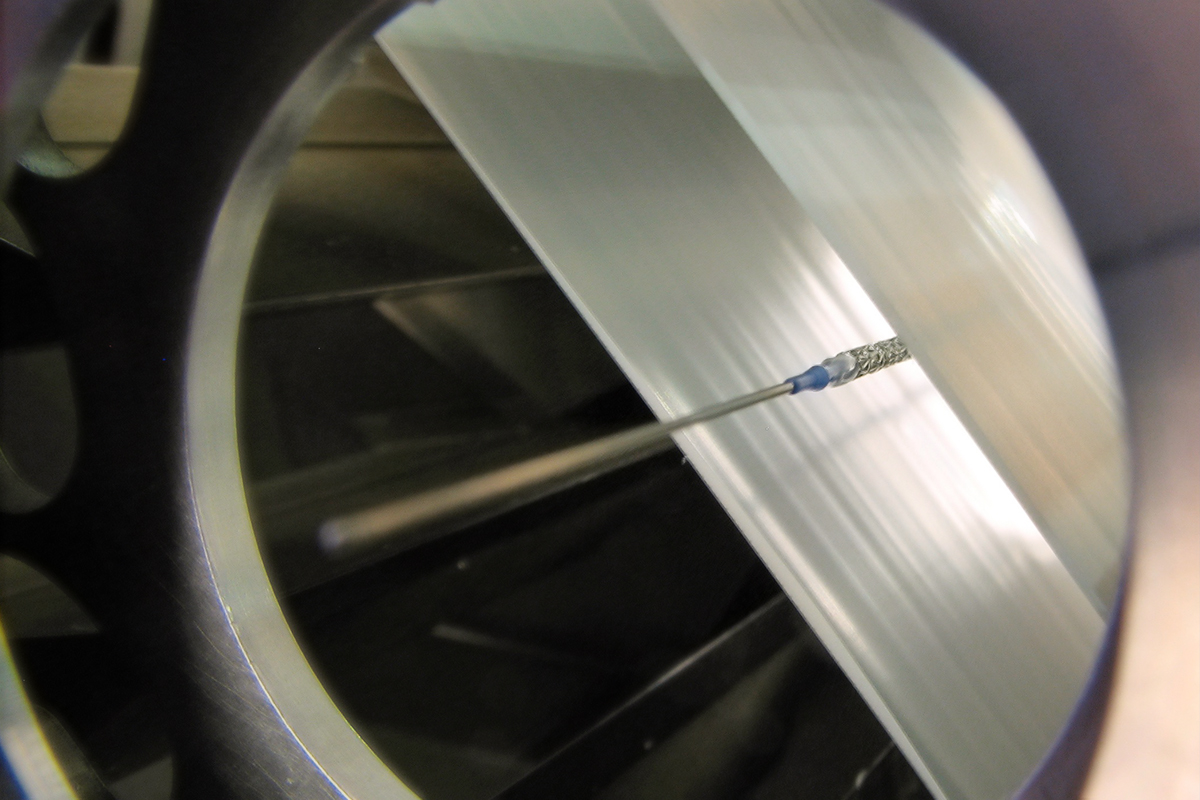

Drug Eluting Stents

Drug-coated stent technology presents its own manufacturing challenges. MSI offers a specialized machine base for crimping coated products. This design integrates Teflon film to protect coatings on the stent’s surface and prevents cross-contamination while achieving the uniform compression manufacturers rely on. MSI’s one-of-a-kind technology ensures high production yields and significantly reduces cycle times.