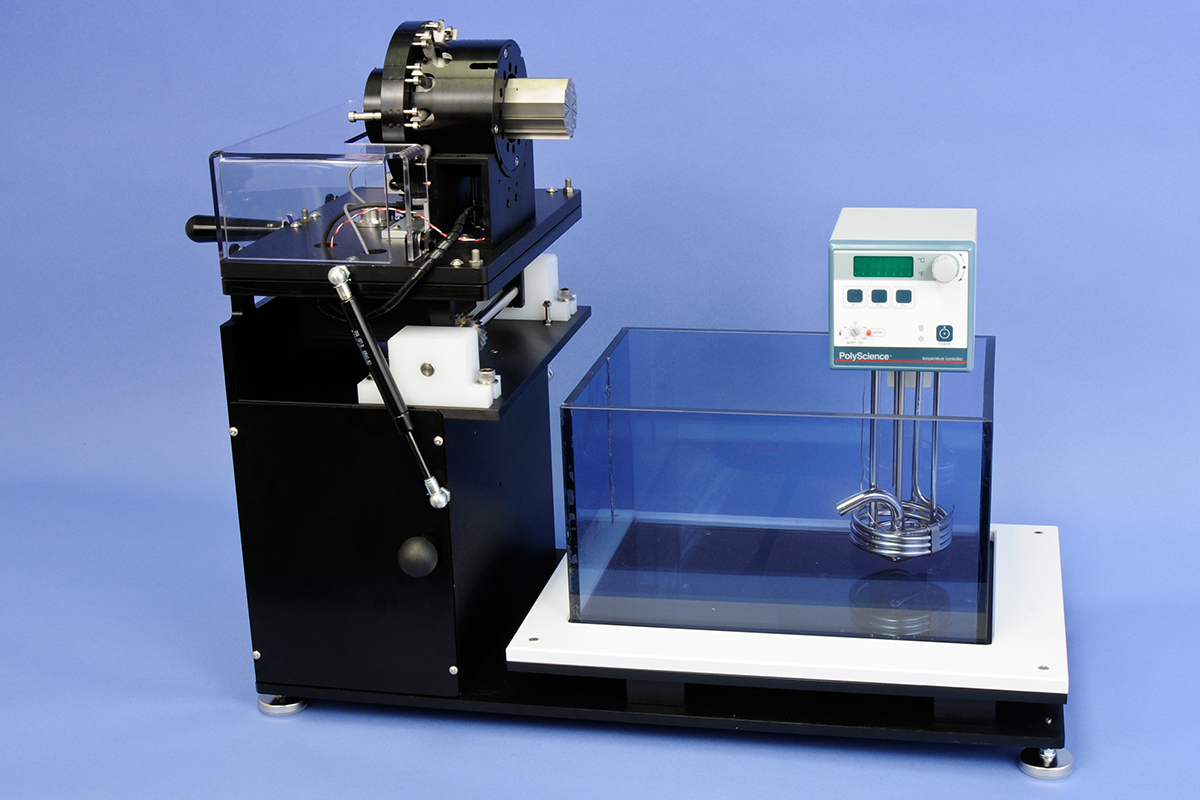

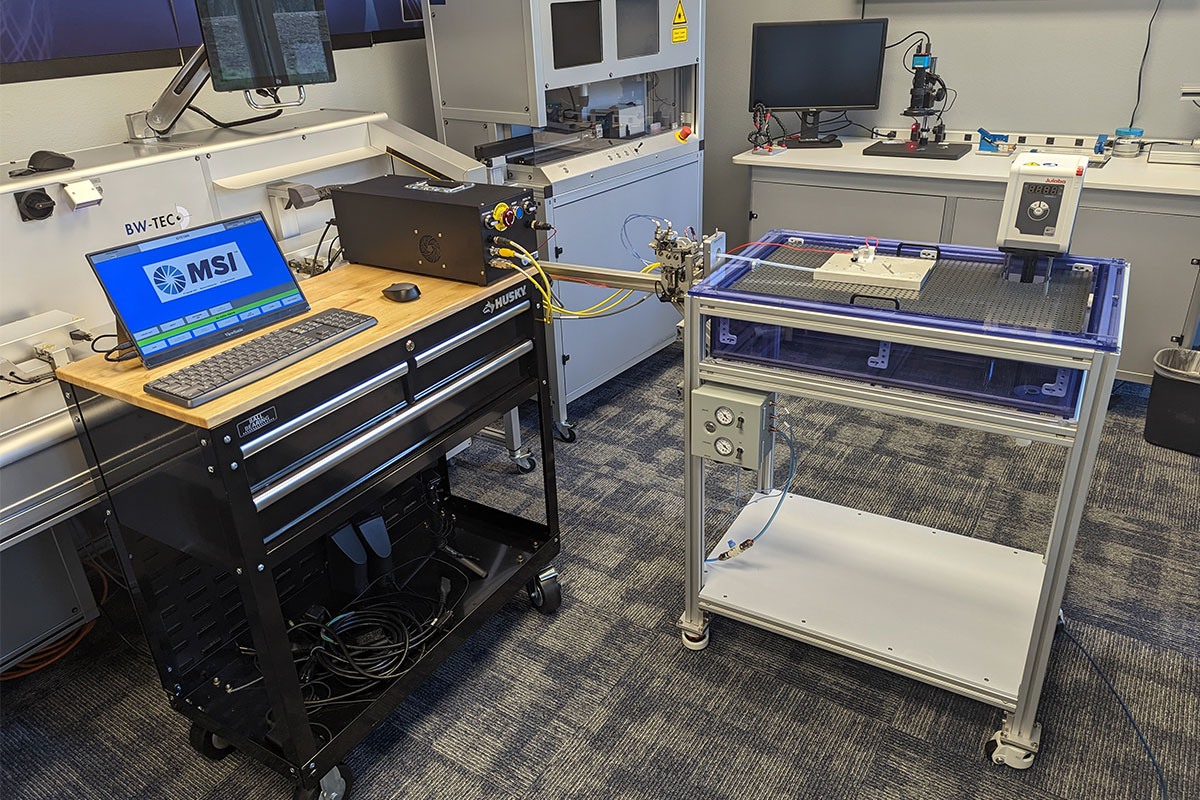

Radial Force Testing (wet)

Product Features

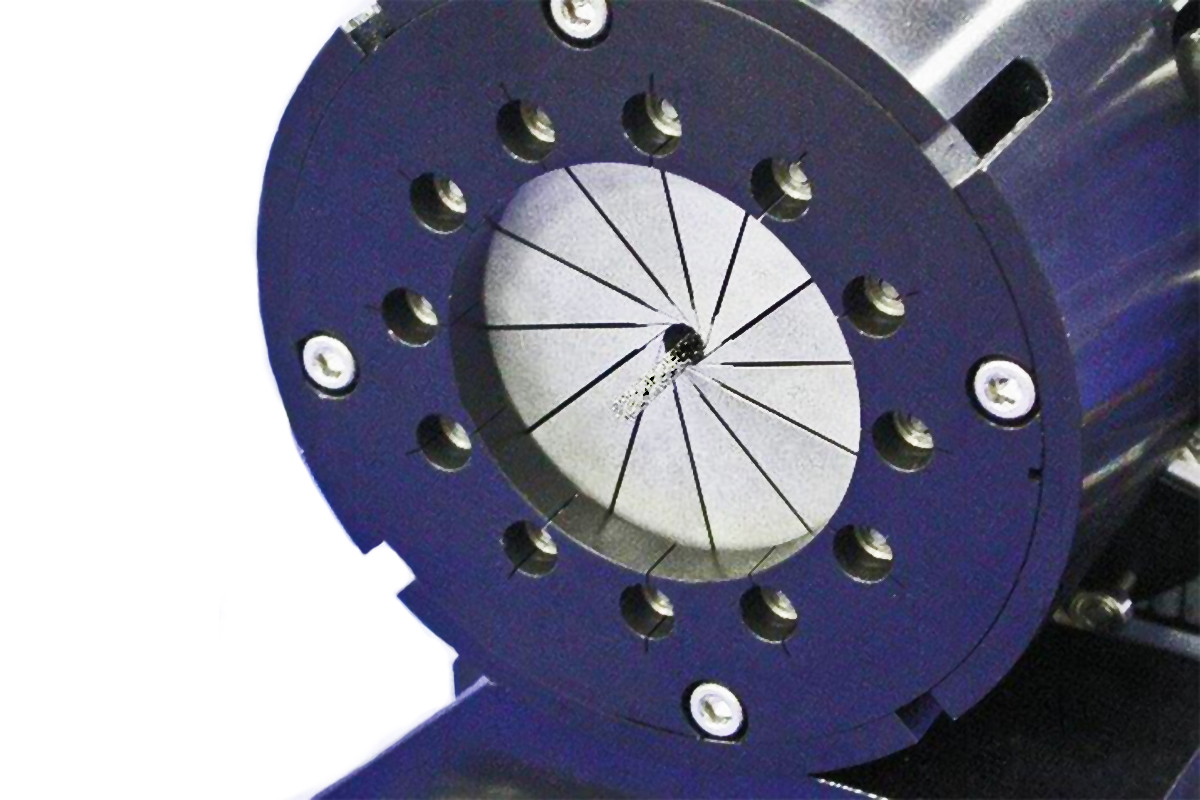

- Submersible segmental compression mechanism

- Ideal for testing polymer scaffolds and living tissue heart valves

- Polymer scaffold will have different radial strength when tested in aqueous environment

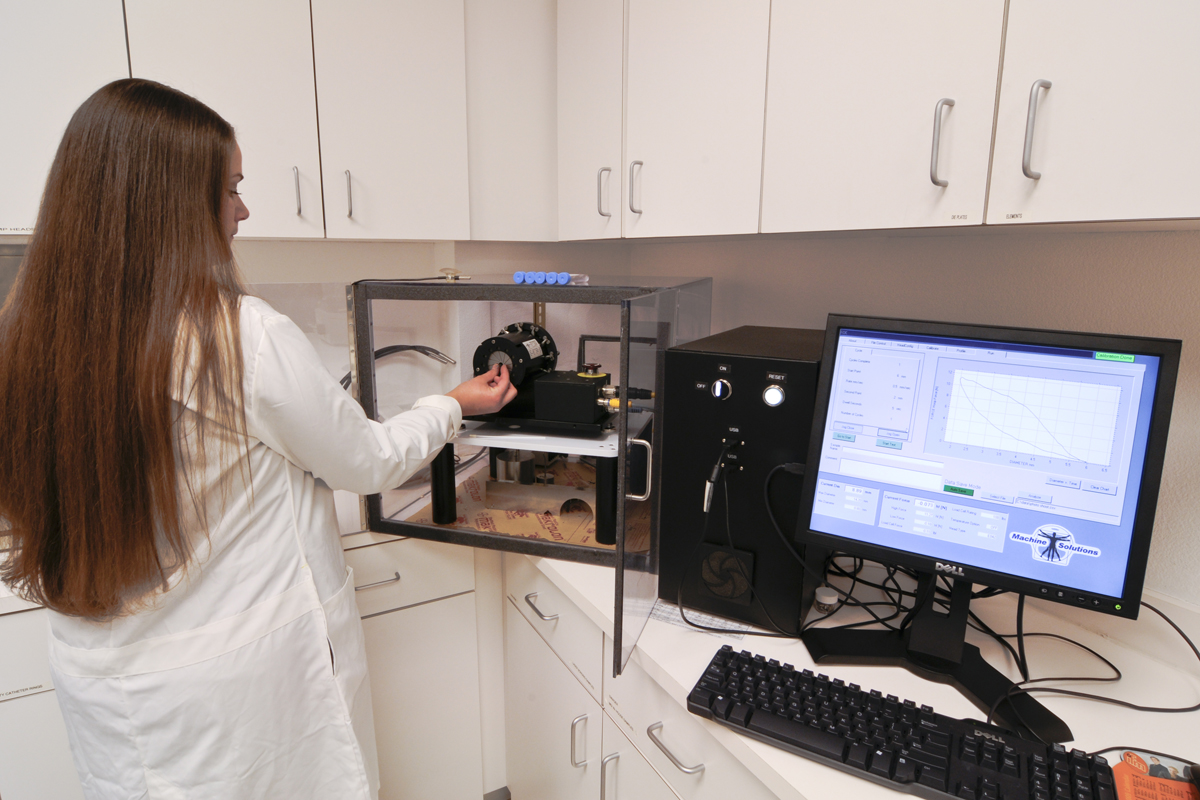

- Repeatable and reproducible data

- Software capable of replaying multiple data sets for fast and easy comparisons

- Force control capability for measuring diameter creep over time

- Data output optimized for spreadsheet analysis

- Interchangeable load cells for optimal force resolution

Spec. Sheet Download

© 2026 MSI. All rights reserved. Designed and developed by: Tension Design