Radial Force & Hoop Force Testing

The industry standard for radial force and hoop force testing

Deliver Quality and Value

MSI’s radial force testing equipment applies MSI’s patented technology to international testing recommendations to compress cylindrical stents and measure the diameter change and hoop force. This equipment measures and records device characteristics including radial stiffness and strength, chronic outward force during expansion and radial reactive force during compression. The equipment has the capability to display force outputs in various units of hoop force, radial force or pressure. Radial expansion testing has been used for a variety of interventional devices, including balloon expandable stents, self-expanding stents, stent grafts, collagen plugs, embolic filters, vena cava filters and more.

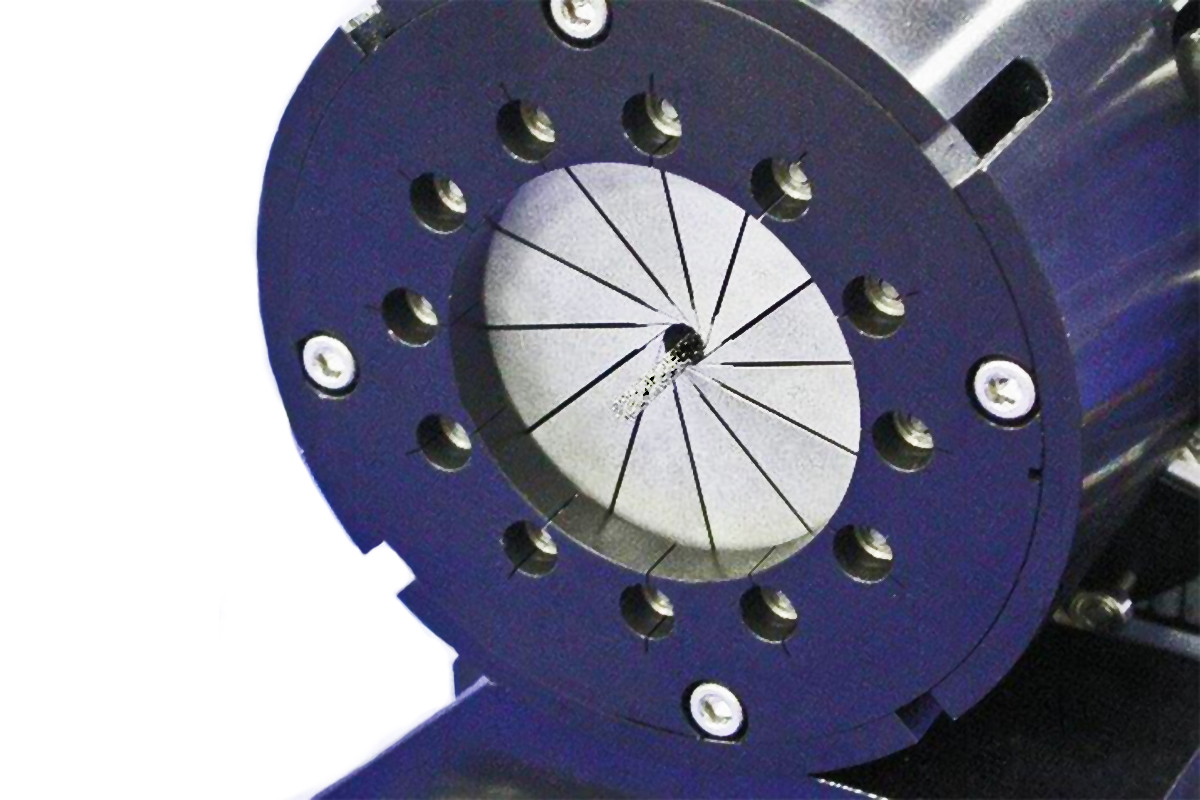

Segmented Head Apparatus, such as the MSI RX equipment, is specifically called out it ASTM standard F3067 – 14 Guide for Radial Loading of Balloon Expandable and Self Expanding Vascular Stents as a preferred apparatus for collection of radial force or hoop force of a stent like device.

Proven Innovation and Expertise

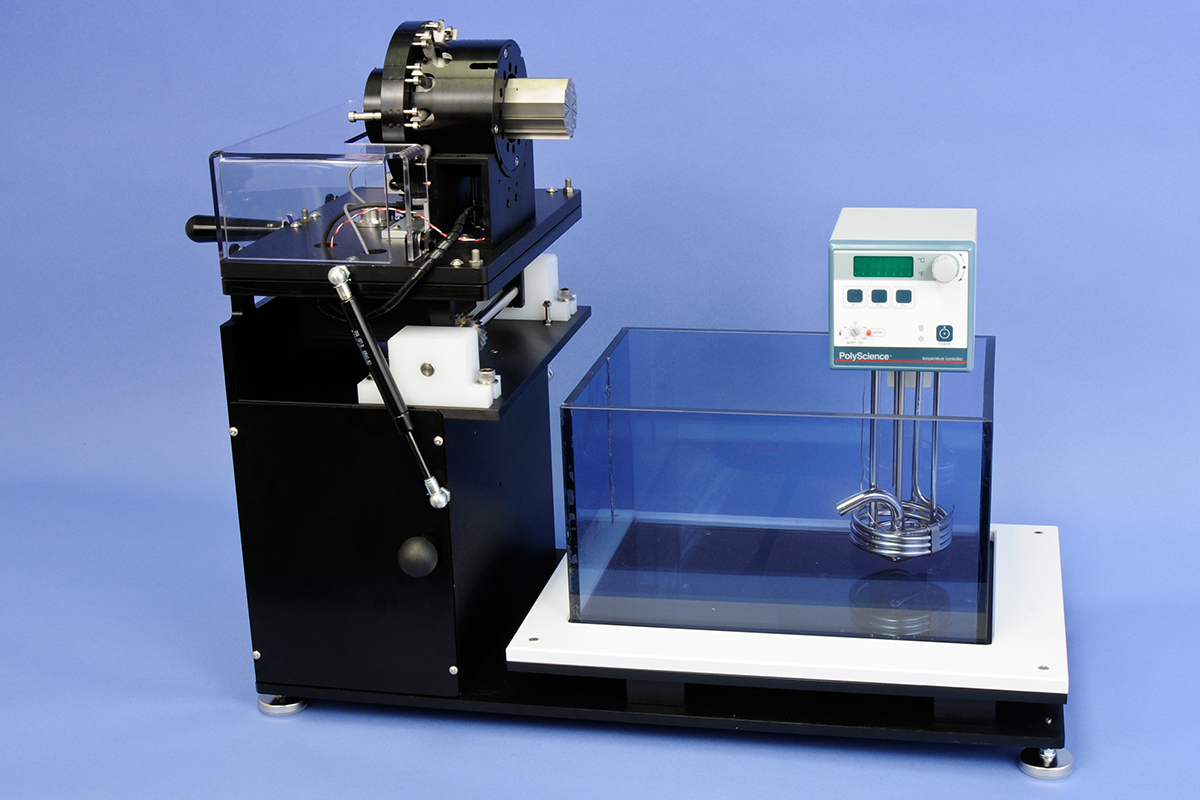

MSI provides the best equipment for device evaluation and inline manufacturing quality testing. We use highly precise sensors such as encoders (for diameter accuracy), linear actuators (for activation) and precision roller bearings (for low-friction testing).

FDA guidance 1545 Non-Clinical Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systems specifically requires testing of “stent diameter as a function of uniformly applied external radial pressure”. Our proprietary segmental compression mechanism collects data from 12 product contact points, providing uniform radial measurement collection of radial force, hoop force or pressure.

Ease of Use

In addition to accuracy and repeatability, MSI testing equipment offers unparalleled ease of use. With our equipment, you can quickly and easily run software-controlled calibrations and set up tests, and data output is comprehensive and accessible, featuring spreadsheet analysis of lab notes and maximum, minimum, and average force. You can rely on your testing results to inform knowledgeable and rapid device design changes.

Features and Capabilities

The segmental compression head is compact enough to fit entirely within a temperature chamber for economical environmental control. Data acquisition is automated through a high-speed data acquisition system that interacts with an improved motion control system and high-resolution force and diameter sensors. Data outputs are optimized for spreadsheet analysis, and include lab notes as well as maximum, minimum, and average forces. Software that replays multiple data sets demonstrates the repeatability and reproducibility of test data.

Superior Customer Experience

MSI offers contract testing services so that customers can evaluate the test system prior to purchasing. Our team in Flagstaff, AZ would be happy to host your visit or run evaluation samples to prove our capabilities. Installation and training of the equipment is a breeze as our trained technical staff will visit your facility and teach your teach about standard test methods and calibration. We also offer an optional IQ/OQ documentation package for the RX equipment to support your validation activities.