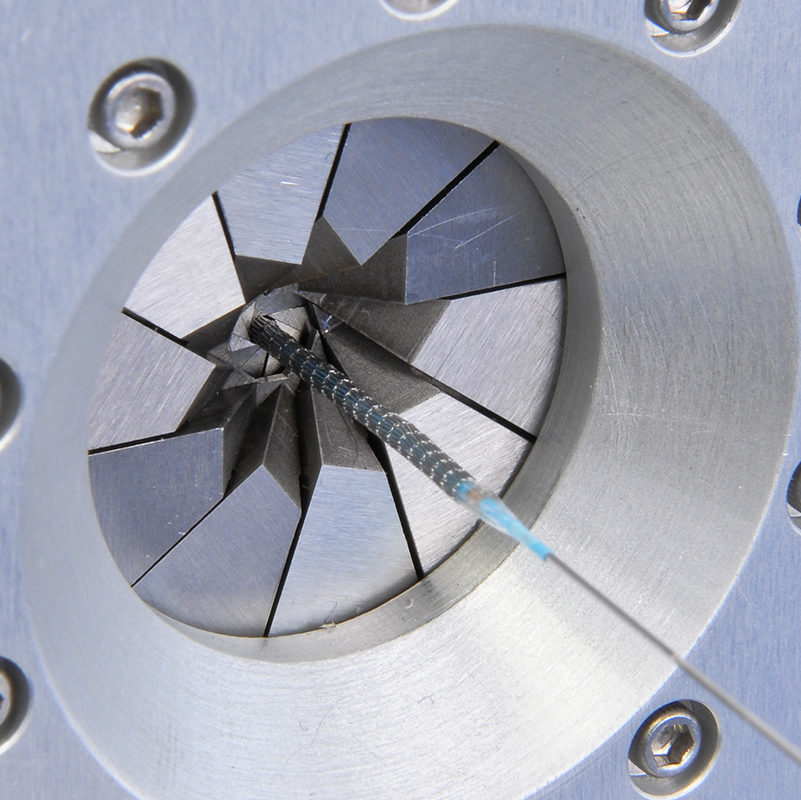

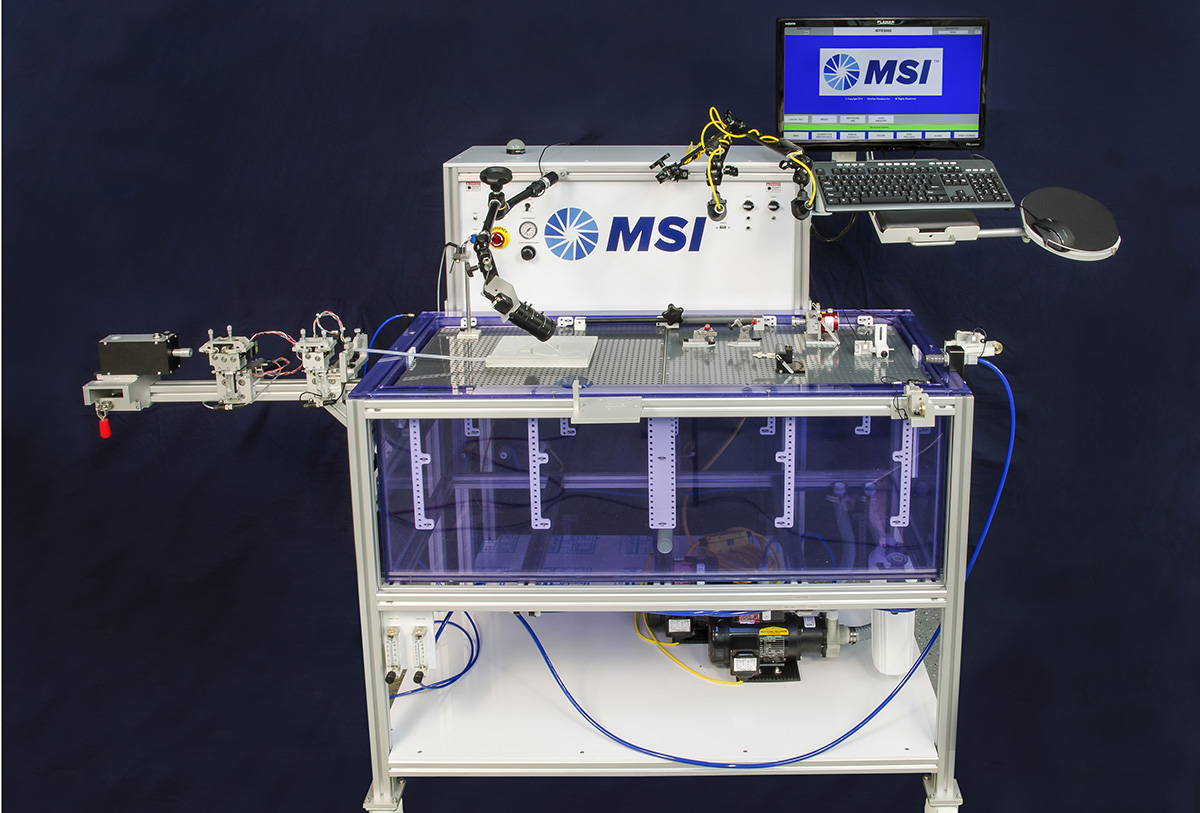

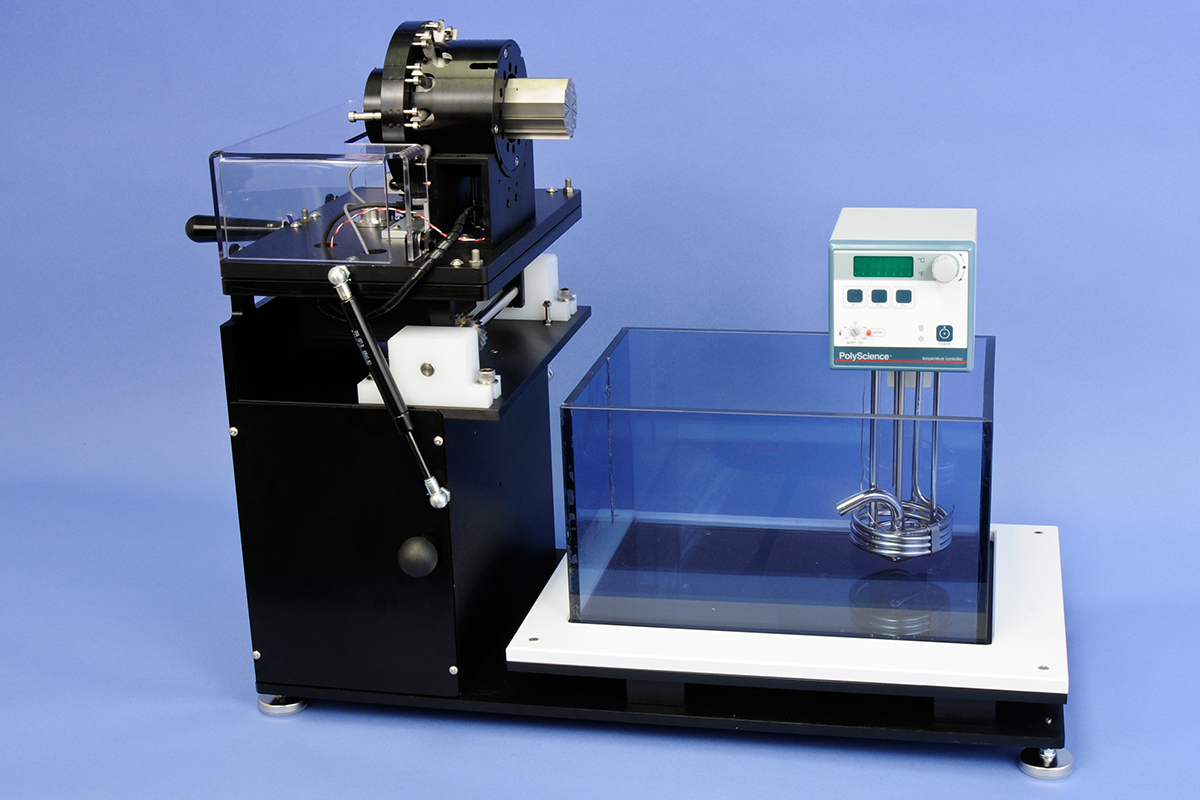

Stent Securement Testing

Product Features

- Proven to have lowest standard deviation in test results compared to tape and shim methods

- Reduce the number of samples required to get statistically significant results

- Allows R&D team to optimize stent crimping process settings by providing meaningful test data

- Designed to meet requirements of ASTM F2394-07 (2013) test standard

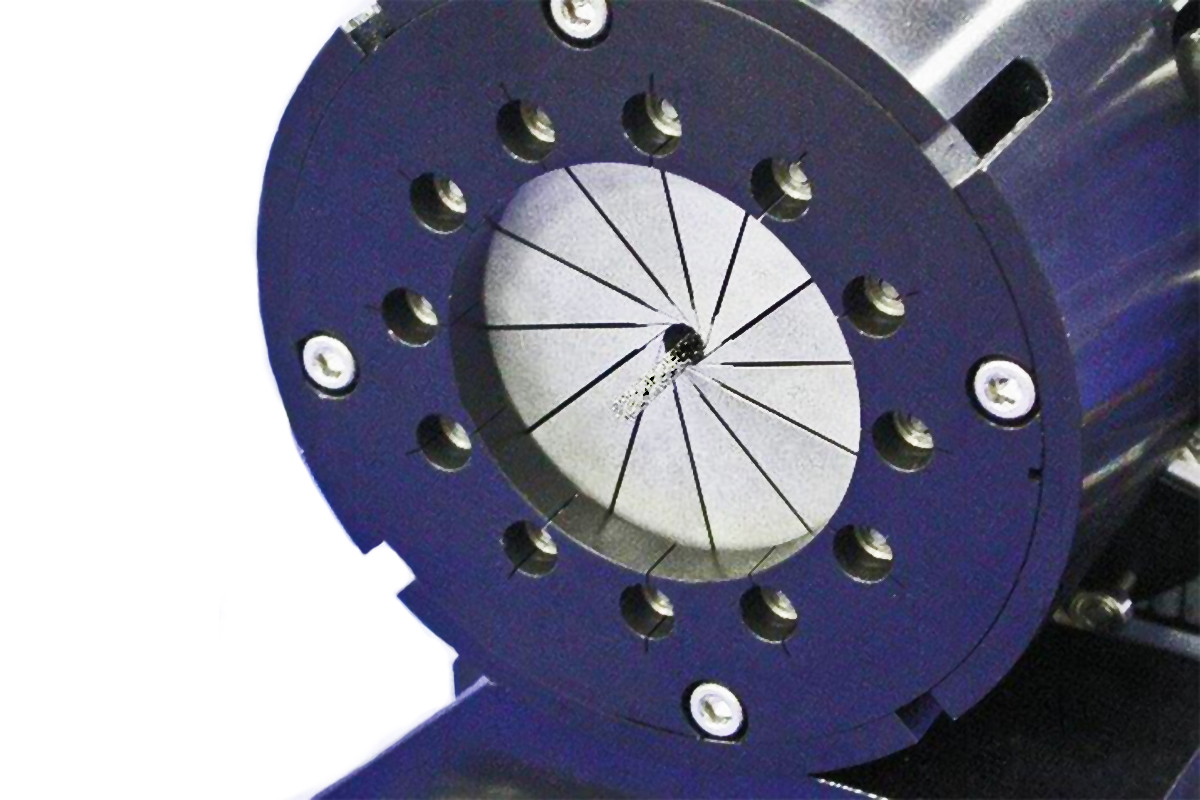

- Automatic self-centering design allows any operator to get repeatable results

- Adjustable shim diameter to minimize frictional impacts of catheter

- Video assist with sample alignment and video capture of test

Spec. Sheet Download

© 2026 MSI. All rights reserved. Designed and developed by: Tension Design