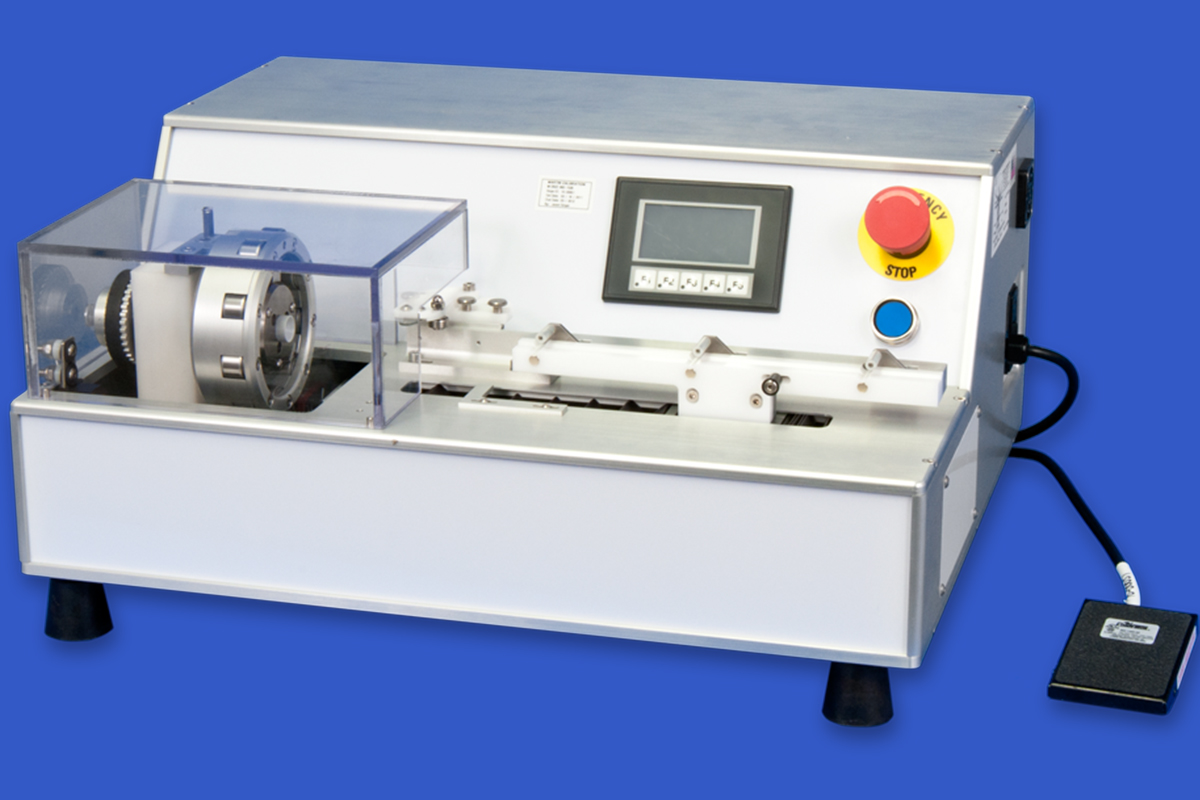

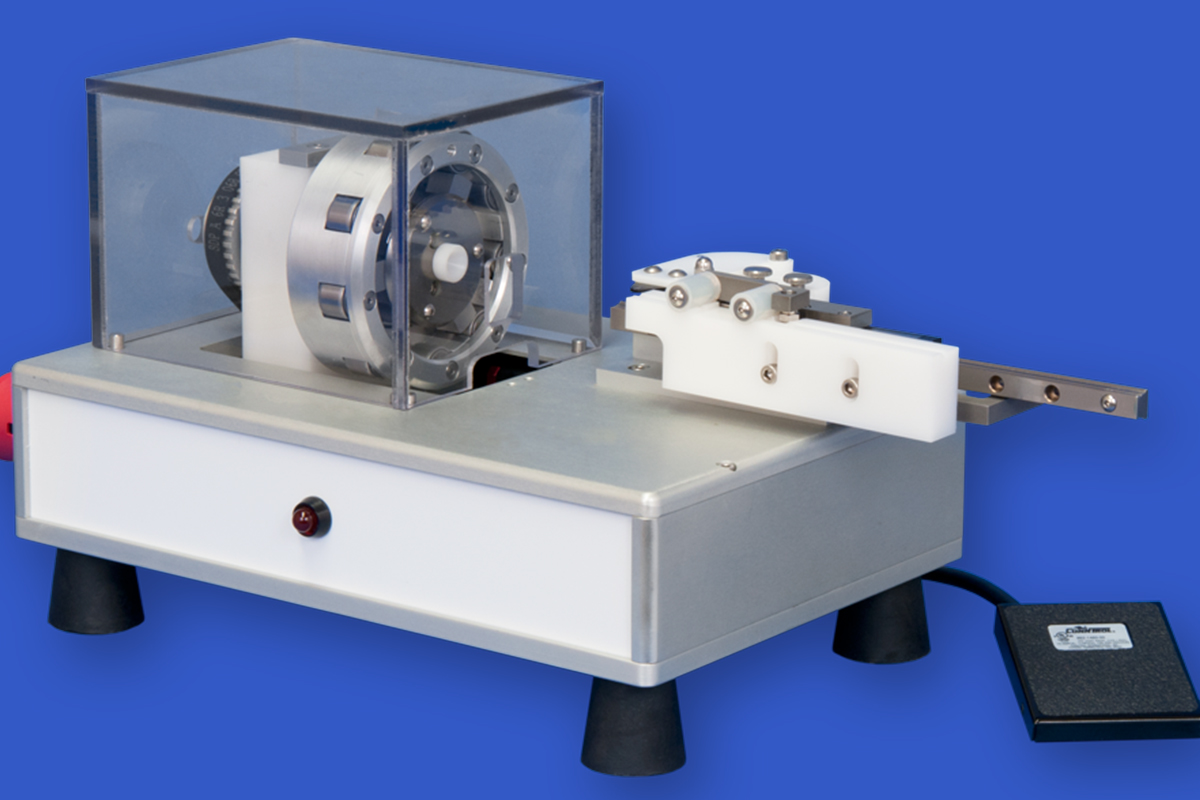

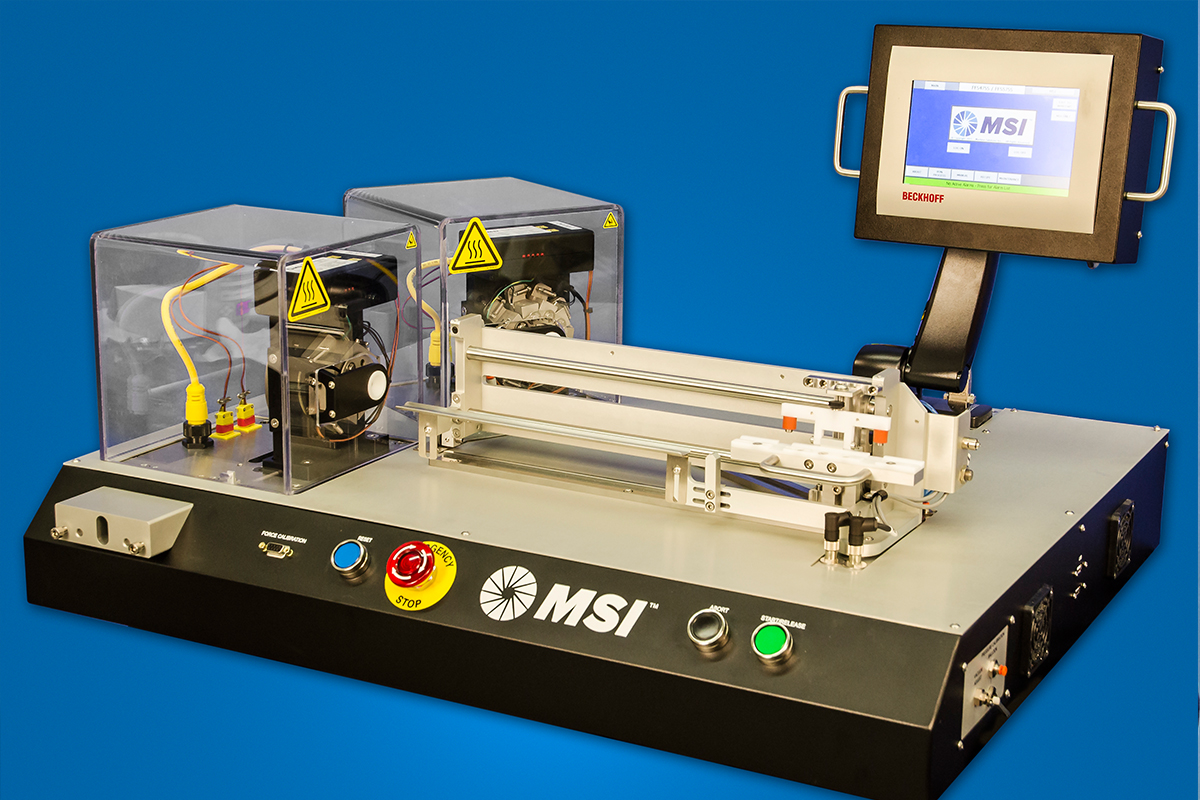

Production Marker Band Swager

Product Features

- PLC controlled

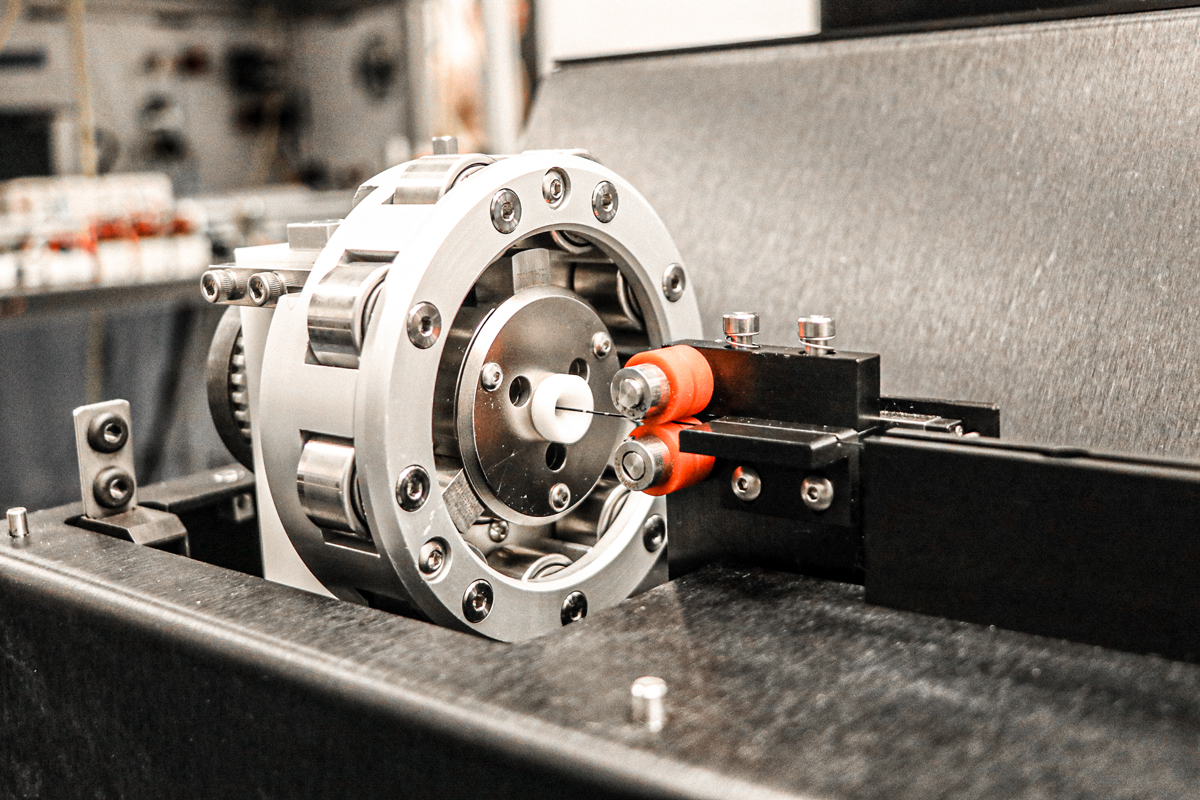

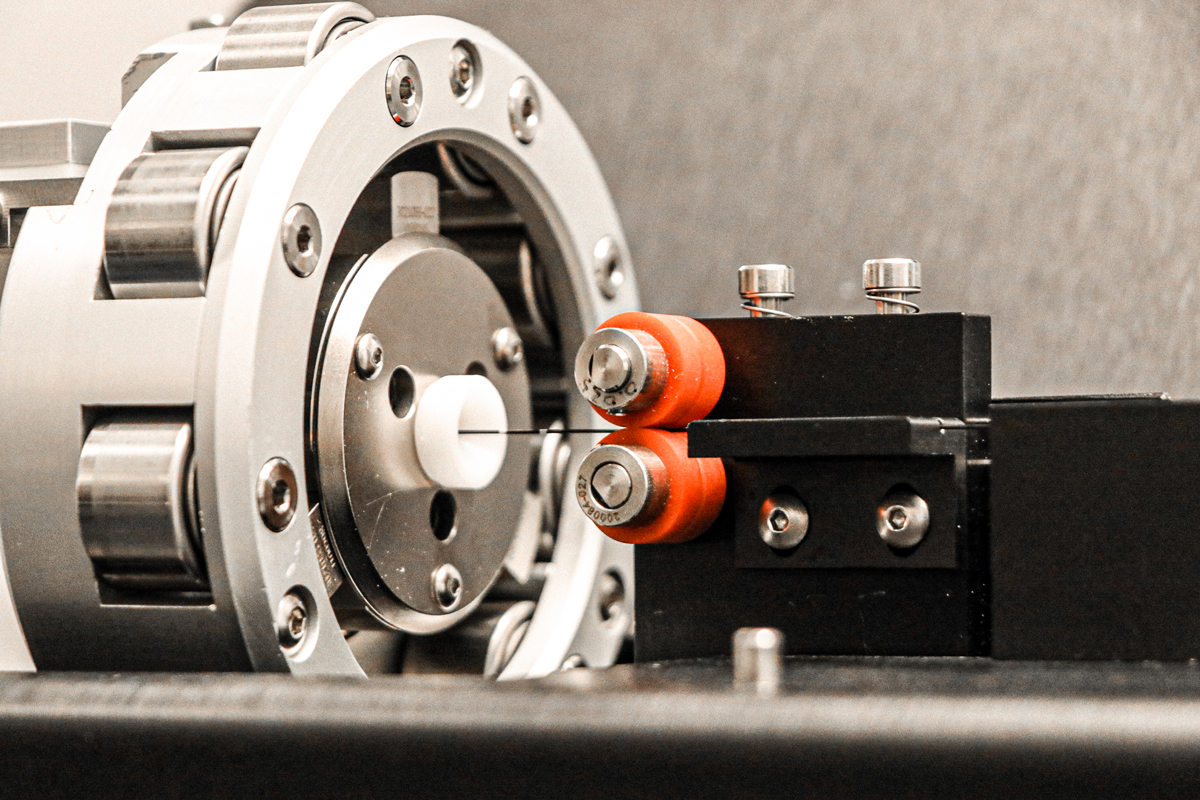

- Three element, quick change design

- Automated handling system

- Swages a wide range of materials

- Low maintenance, space-saving design

- No lubrication required

- Clean room ready

Spec. Sheet Download

© 2025 MSI. All rights reserved. Designed and developed by: Tension Design